Wave Power: Stabalizing the Future Clean Energy Mix

Wave energy has not yet experienced the same curve of acceleration as offshore wind and solar. However, the technology is now fast evolving and edging ever closer to widescale commercialization.

CorPower Ocean CEO Patrik Moller explains how wave power can play a crucial role in the future clean energy mix helping stabilize energy production through combined wind-wave-solar arrays.

The ocean forms one of the largest yet least explored energy sources on earth—and the successful conversion of wave energy is likely to play a crucial factor in our transition to an entirely renewable world. Wave energy is particularly valuable in the broader clean energy mix because its consistency and predictability. As waves are built up from weather systems over several days the energy content is concentrated and smoothened, delivering a regular power profile to our coasts.

Essentially, wave energy can fill the gaps when it is not windy or sunny. This adds stability to the electricity system in a reliable and competitive way. By producing electricity at times when it is most needed, wave energy offers natural grid balancing that both reduces the need for over-capacity of wind and solar and reduces the need for storage capacity in zero carbon electricity systems. Ultimately, this lowers overall system costs and unlocks greater value for farm owners and grid operators.

It also works hand-in-hand with hydrogen production, with a wind-solar-wave electricity mix offering a more constant operation with higher load factors and higher profitability for electrolyze operators. In the lowest cost zero-carbon scenarios, renewable hydrogen will be used primarily for industry and transport, while wave energy and other complimentary electricity sources help balance the electricity system without requiring as much long-term storage capacity.

STORMPROOF ENERGY EFFICIENCY

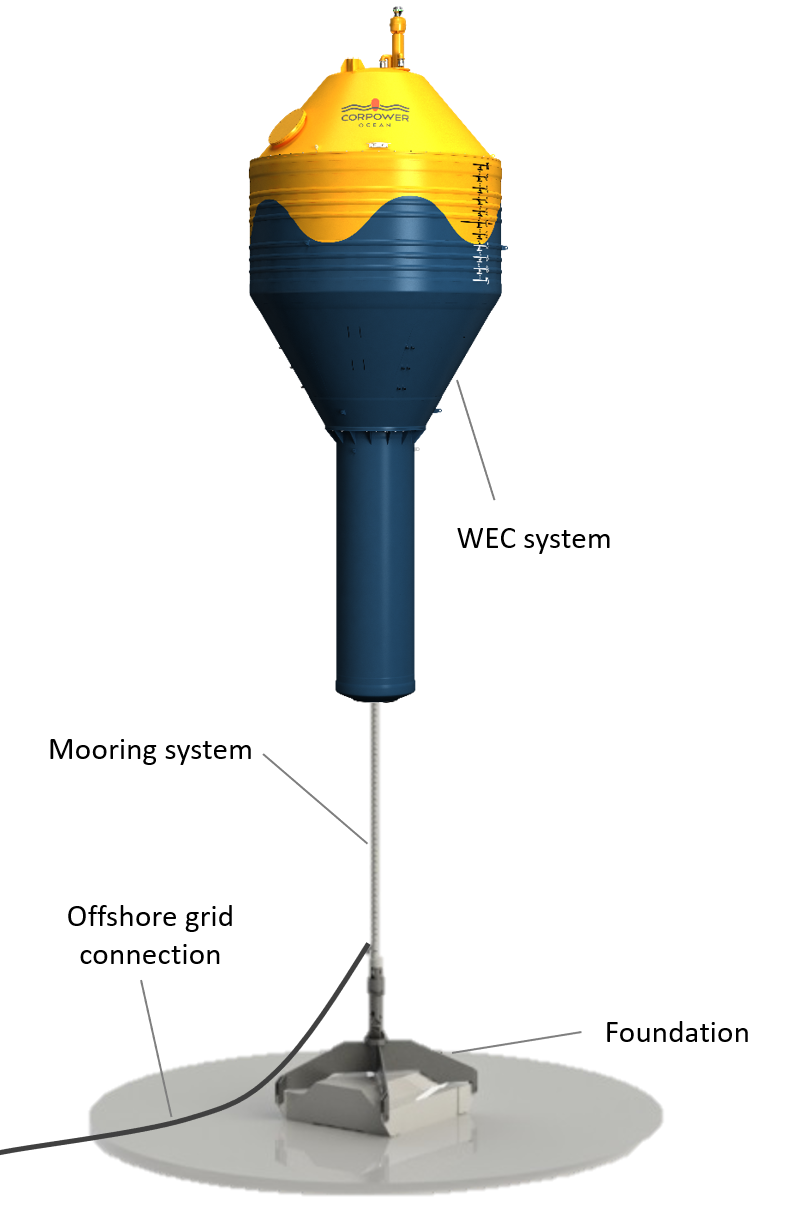

CorPower’s unique WEC (Wave Energy Converter) technology took inspiration from the pumping principles of the human heart, which pumps in a singular direction, using stored hydraulic pressure to provide force for the return stroke. CorPower’s devices—which come in the form of heaving buoys connected to the seabed through a tensioned mooring system—mimic this action harnessing the upward force of a wave swell and storing pressure to provide return force driving the buoy downwards. This results in equal energy production in both directions. The device harnesses energy from both the rise and fall as well as the back-and-forth motion of waves. When stimulated, the light, composite buoy initiates a ‘Power Take Off’ in the form of a drive train located inside which converts the mechanical energy into electricity.

Historically, wave energy devices have either broken in storms or simply not produced enough electricity to make it a viable business prospect. CorPower is addressing those two main challenges head on, firstly by using new technology to protect its devices making them transparent and resilient to the most aggressive storm waves. This function is similar to wind turbine technology where blades will pitch to protect from overspinning in fierce conditions. This sort of protective function has been missing in wave energy to date.

The second key development is advanced phase-control technology, which strongly amplifies the response to regular waves in terms of the motion and power capture. For instance, in a one-meter wave, CorPower’s buoys may move three meters up and down, due to the resonance phenomena. Its devices have been shown to produce five times more electricity per ton than any other known wave technology. On average the devices generate 10Mwh per ton of equipment installed in the ocean, which is in line with leading floating wind developments.

HARVESTING BIG ENERGY

CorPower’s relatively small and low-cost WEC device have been designed to harvest large volumes of energy due to their high structural efficiency. The devices are engineered to generate the same AEP from a buoy with 1/10 volume compared to conventional point absorber WECs. In terms of dimensions, the devices measure 9 by 19 meters and weigh 60 tons—dwarfed by the size of other wave energy prototypes some of which are thousands of meters in dimension and weigh several thousand tons yet have the same capacity. Securing large amounts of electricity from a small device significantly reduces CAPEX, while the compact lightweight devices are also less costly to transport, install and service, bringing down OPEX.

The device concept is optimized for 10MW clusters, where the electricity is collected from an array of WECs into a collection hub. Each 10MW hub delivers grid quality electricity with standard 33/66kV electrical connection commonly used in offshore wind, with a single control and data acquisition interface over fiber and radio-link to the hub. A programmable logic controller located inside the devices enables them to operate autonomously.

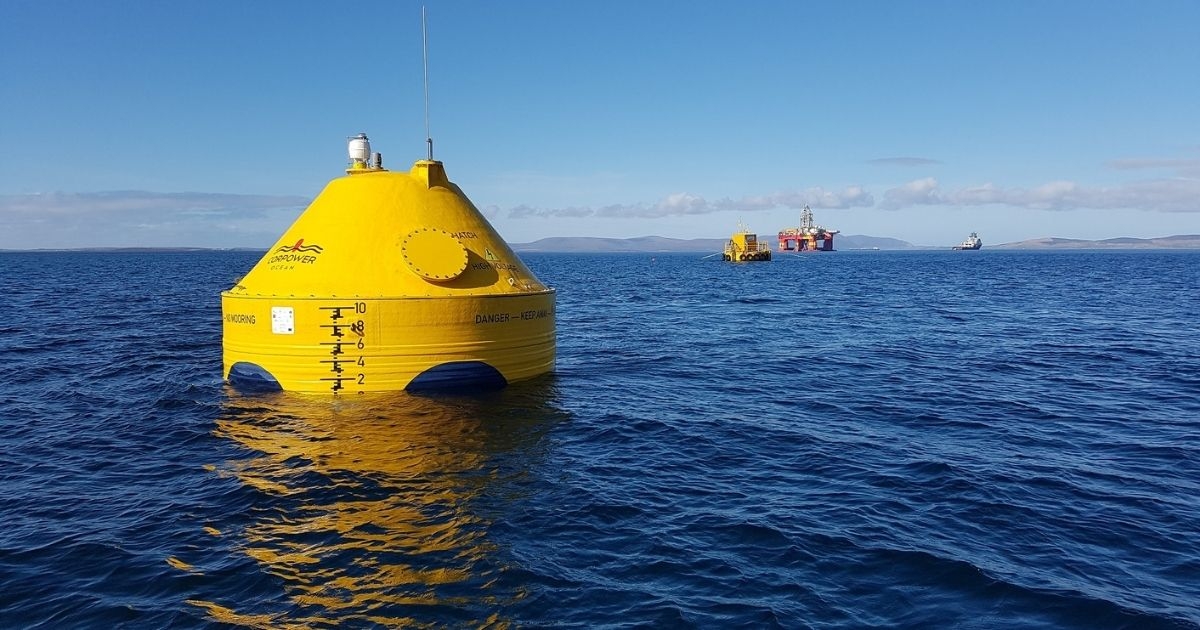

CorPower's HiWave-3 demonstration project involved a large scale (1:2) WEC system which was designed, manufactured and tested in two steps between 2015 and 2018. (Image credit: CorPower Ocean)

CorPower's HiWave-3 demonstration project involved a large scale (1:2) WEC system which was designed, manufactured and tested in two steps between 2015 and 2018. (Image credit: CorPower Ocean)

RACE TO COMMERCIALIZATION

The firm is now entering the final stages of its journey to commercialization, after modifying and refining this technology for more than a decade. In 2020, CorPower announced a major 16 MEUR expansion in Viana do Castelo, northern Portugal, where it aims to complete the final demonstration phase branded Hi-Wave 5. The broader project will see the development of an R&D, Manufacturing and Service Centre laying foundations for future high-volume operations.

Example wind-wave array. CorPower’s WEC technology has resulted from a decade of product development and three decades of research on wave hydrodynamics. (Photo credit: CorPower Ocean)

Example wind-wave array. CorPower’s WEC technology has resulted from a decade of product development and three decades of research on wave hydrodynamics. (Photo credit: CorPower Ocean)

The team is currently in the process of fabricating its first commercial scale system before undertaking dry testing in a bespoke test rig with simulated wave loading in Stockholm before ocean deployment during the second half of 2021. The full-scale device will need to demonstrate it can survive the harshest ocean conditions through a rigorous testing process. CorPower will then complete one more design update before unveiling the final commercial stage technology in the form of its C5 machines. A total of three C5 machines will be installed in the ocean in 2023 running for a little of over a year to secure type certification. The longer-term future will see CorPower positioning itself as a leading global OEM (Original Equipment Manufacturer) building devices, completing final assembly and also offering operations and maintenance contracts to customers operating the wave farms worldwide.

This feature originally appeared in Ocean News & Technology's Magazine January 2021 edition—The Essential 2021 Offshore Toolkit. To read more, access the magazine here.