The Future of Power & Control in the Deep Ocean

Electricity is the magic power behind the vast spectrum of our ocean projects. Jules Verne understood this more than 150 years ago when he wrote about the Nautilus, a vessel that circled the globe underwater using a new form of energy he simply called “electricity.”

He does not explain where this energy comes from or how it is stored. The suspension of disbelief was enough for his audience.

Electric motors are no longer a novelty; they are almost a commodity and have a central place in the future of subsea applications. Their simplicity and heritage of reliability are a matter of record. Today, they are often treated like a Lego block, easily snapped into a larger design. Just pick the right color and size and continue with the high-tech aspects of the system. The reality is that the electric motors are often critical elements in a new system and its specifications can benefit immensely from early design evaluation to ensure it is practical and cost effective. This is true for any subsea motor but especially so when larger horsepower units are specified.

One advantage in subsea systems design is that we can borrow from aerospace, land, and defense industries. The major challenge in subsea, however, is the low volumes and controlling cost while in many cases these also require additional customization. The problems with fully custom solutions are not only cost and lead times but also the issue of qualification testing for new systems. The first instinct is to use existing off-the-shelf components and make the solution subsea compatible, by enclosing components in a pressure vessel. This can prove to be a lot harder than it looks, particularly for high power electric systems, which involve a lot more than just the motor.

HIGH POWER ELECTRICAL SYSTEMS

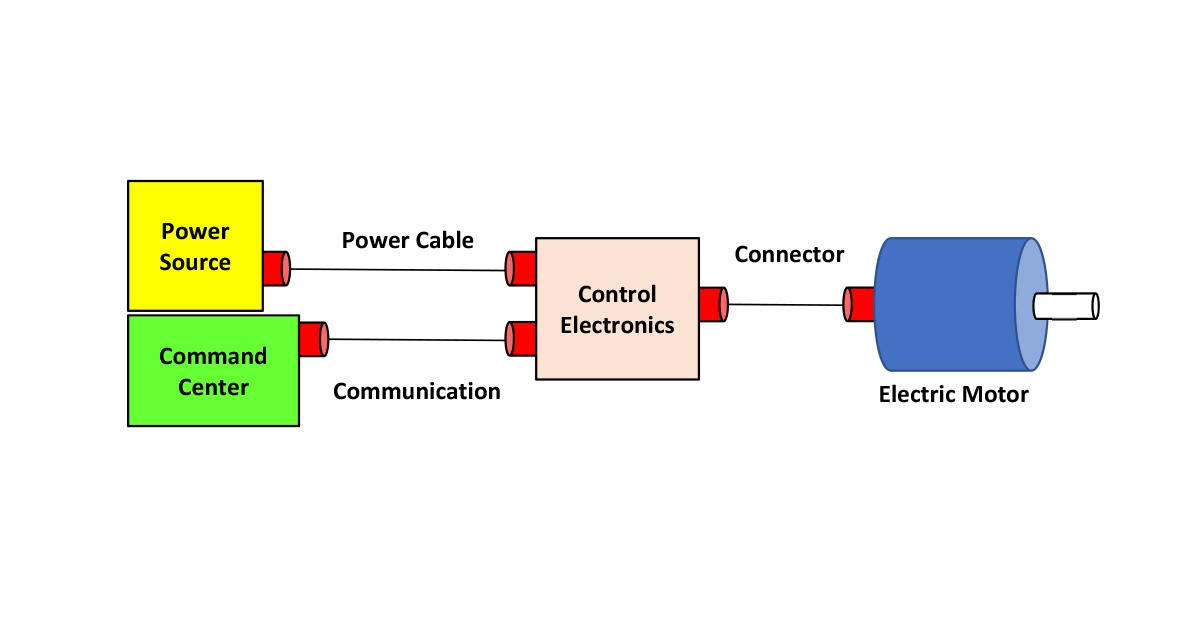

Subsea electric control systems consist of four primary elements: 1) Power Source; 2) Control Electronics; 3) Electric motor; and 4) Connectors. Selecting the power source specifications is an important step that can affect the cost and complexity of all four elements. The fifth element, the communication between the motor controls and the command center, is less affected by the power level but equally critical in the ability to interface with various control platforms.

Electric motors can be fabricated in any size, weight and dimension. Size and space constraints are often the primary driver, followed by the HP specification. High torques require either large motor dimensions (length, diameter, or both) or high motor currents, or both. High currents affect the motor size but also cost and complexity of the electronics and the connectors. After torque, considerations turn to speed requirements. In general, higher speeds also require more voltage to keep current levels in the “reasonable” range. This is a bit of an over-simplification, but it provides a helpful guideline. These combinations can make it difficult to evaluate a design. We can, however, map the current levels required for specific shaft HP levels according to specific system voltages (as pictured). High voltage systems are more sophisticated and expensive, but low voltages also have practical limits and can present serious cost and reliability impacts.

DESIGN FOR HI-RELIABILITY

Designing for high reliability requires additional consideration of the parts that wear or degrade. For electric motors, the bearings and seals are central to long life and designing for lower speeds improves life. An additional degradation element is current. Ratings of connectors, cable and electronics will typically have more problems dealing with high current levels than high voltage. All these considerations impact a design when reliability is a requirement.

It is helpful to divide system currents in four categories, by complexity and cost. It shows how controllers and connectors up to 25 amps are a well proven technology. Systems delivering 25-50 amps are more advanced and can serve power levels up to 25 HP but will require higher voltages. Designs that can accommodate 50-100 amps become a more difficult but new developments in high voltage electronics offer excellent form factors for future electric motors in the 40-50 HP range.

System designs with motor currents > 100 amps are extremely demanding, become expensive, and should lead the designer to question whether this is necessary. In addition, qualification testing a custom connector to 150A at depth can be an expensive enterprise. While not a hard and fast rule, the table below provides a useful arms-length guide to the level of complexity of connectors and electronic controllers.

Of course, there are more parameters in a design tradeoff, but it is good to keep these in mind at the system design level. The finer details and optimizations can be discussed with technical experts. There are many more conditions and details that affect a design but too complex to address here.

FUTURE HI-RELIABILITY SYSTEMS

The subsea industry has access to high power levels through umbilical cables as well as high energy batteries. New technology developments in electronic controls make new high power design options available. Some electronics are pressure tolerant, many more are not. Leveraging on commercial land-based solutions in this power range is smart but not always a simple process. Generally, the form factor of industrial controllers is square or rectangular and not volume efficient to fit inside a cylindrical pressure vessel. Thermal management is also a critical difference, especially for electronics. While the sea provides an infinite heat sink, getting the heat out requires careful analysis.

There are more challenges in these future systems beyond power. New systems demand more control options and can benefit from remote diagnostics. Systems are operated remotely and managing data rates of long communication lines is challenging. This encourages designs to prioritize local control processing to reduce data transmission. Smart actuators, for example, with resident intelligence and an integrated uninterrupted power supply can provide local control to achieve a safe mode in case of emergency. There is also the need for some form of communication interface standardization. With the demand for more sophisticated control, digital interfaces are very useful but servicing too many communication protocols gets expensive and difficult to manage. Consideration for TCP-IP standard, CAN Bus, Ethernet are all ideas that are used on land. Agreeing to standard in subsea would be helpful. Industry associations and classification societies can play a part. Above all, it is about providing more cost-effective solutions through better reliability, to be solved with imagination and sound engineering.

This story was originally featured in ON&T Magazine's Special December 2021 issue. Click here to read more.