Redefining the Future of Subsea Robotics

Saipem is an advanced technology and engineering platform for the design, construction and operation of safe and sustainable subsea projects and plants. With an unrelenting drive for innovation at its core, Saipem is fully committed, in partnership with its diverse range of clients, to a clear transition towards a futureproof energy mix, with the increasing integration of digitalized tools, technologies, and processes.

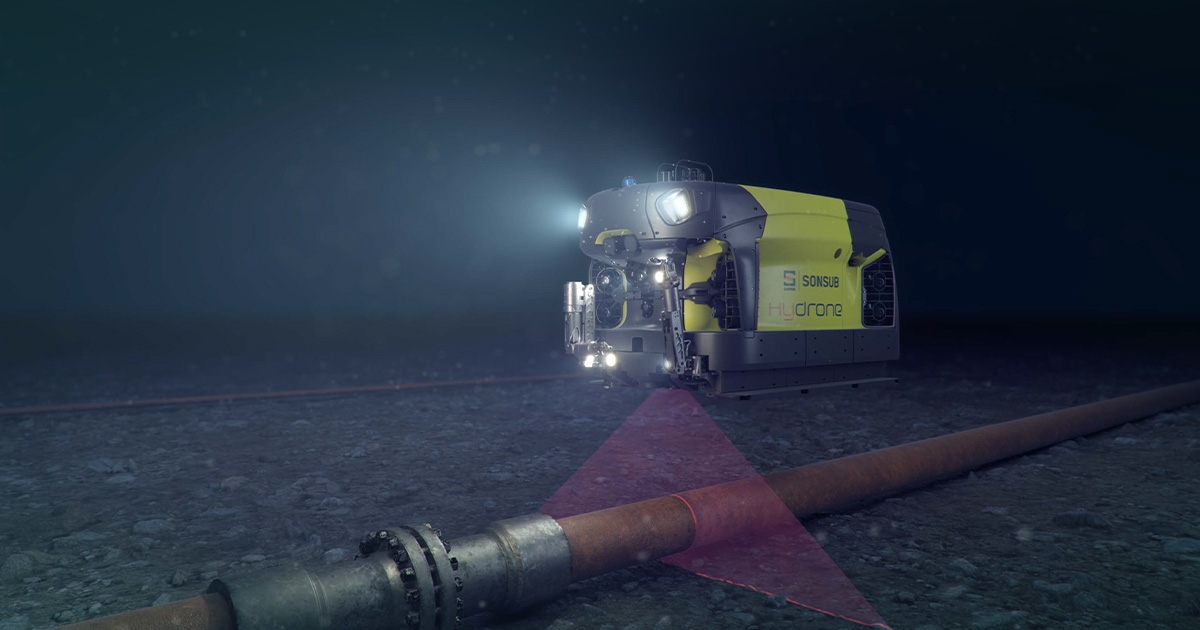

Saipem has a long and established track record in the offshore energy sector, operating in some of the most challenging environments on the planet—few can be as unpredictable as those associated with subsea activities. This extensive experience in the field, including the running of complex projects that have helped redefine traditional subsea infrastructure, has led to the development of several revolutionary and proprietary technologies, including the Hydrone underwater drone program. These intelligent, multipurpose subsea vehicles represent the latest frontier in the field of subsea robotics.

HYDRONE PROGRAM

This technological initiative was dubbed Hydrone to evoke both the natural environment in which these assets operate and a fundamental element of Saipem’s DNA: water. The drones can reach depths of up to 3,000 meters unassisted by any surface cable link and can travel up to 100 km from a particular dive site. All Hydrone program operations are carried out by Sonsub—Saipem's center of excellence for the development of subsea technologies and equipment—which is headquartered in Venice and has several offices around the world, as well as an advanced testing facility in Trieste.

An underwater drone can execute reconnaissance, inspection, and intervention activities below the waterline. Hydrone was initially conceived, designed, and developed to meet the needs of the offshore energy sector, both in the traditional segment and the growing renewables market, and specifically for at-sea energy plants. However, Hydrone also provides the technological and practical solutions for other marine operations, for example, support and inspection activities of coastal and offshore fish farms, as well as the monitoring of public transportation infrastructure, such as submarine tunnels for fjord crossings or bridges.

ENABLING REMOTE OPERATIONS

Drone piloting operations are carried out at a remote command console, fully equipped with monitors and sophisticated systems for data processing. The control room is connected to a satellite or fiber optic communication network to guarantee a direct data link with each submarine drone. Thanks to the AI-enhanced navigation tools, the drones are capable of operating entirely autonomously—that is, without the need for human piloting, intervention, or supervision. In other words, the drone can follow a predefined route, recognize objects, and classify them as obstacles or elements to be inspected. However, manual control is also possible, in which case the pilot is supported by a stereometric view of the surrounding environment thanks to the hi-res real-time images captured by the mounted cameras.

To date, Saipem has developed three models of drone for the Hydrone program: Hydrone-S, more affectionately known as FlatFish, is the most compact and primarily engineered for inspection activities; Hydrone-R, which is the mid-sized drone tasked to execute inspections and intervention activities with its robotic arms and multipurpose tools; and Hydrone-W, the most powerful of the family thanks to its 180kW capacity (approx. 240 hp).

The versatility of underwater drones cannot be overstated. They can be used for a broad range of subsea missions: they can inspect pipes, electrical cables, optical fibers, underwater tunnels, vessel hulls, and mooring lines; digitally reconstruct the morphology of the seabed; count and classify fish; monitor the quality of sea water; control port waterfronts; and perform repair and maintenance operations on critical subsea infrastructure.

SUSTAINABLE SUBSEA RESIDENCY

Compared to other contemporary underwater drones, Saipem’s family of Hydrones share a distinctive and exclusive feature: each model is certified for continuous seafloor utilization, for deployments of up to twelve months. This “resident” configuration requires them to have fixed bases, or subsea garages, for recharging, data transfer, and mission profile upload. However, Hydrone units can also be launched and recovered using more conventional topside operations.

True to Saipem's commitment to green technologies, each Hydrone also has a very low environmental footprint. Today, for the most part, subsea inspection operations are reliant on support vessels to deploy tethered or tetherless marine robots but removing this topside dependency—given that these drones can just as easily be launched from an at-sea fixed platform or onshore jetty—not only helps reduce a developer’s operational costs but also drastically curbs their associated carbon emission and HSSE risk exposure.

When in resident mode, Saipem’s Hydrones can be deployed remotely at a moment’s notice to inspect pipelines, monitor manifolds, detect leaks, and so on. In terms of aquaculture, the drones can also be used for cleaning fish farm tanks and to monitor the overall health of the fish through sample analysis of movement and behavior.

FUTURE INVESTMENTS

Saipem has several projects underway that will, over the next three years, enable the remote operation of drones in swarm formation for extensive hydrographic activities. As part of the same program, Saipem’s subsea engineers are working on the miniaturization of drones for applications that demand greater accessibility and maneuverability in confined spaces. A plan for the development of far-reaching underwater Wi-Fi networks with wide coverage is also in the works and will ultimately be one of the prerequisites to establishing the future digitization of underwater infrastructures.

Saipem is also working on the concept of an exclusive fuel cell powered vessel that, in its initial phase, will be operable from land and, therefore, only require a minimal onboard crew. Phase two will introduce completely autonomous operations. Engineering of this nature is integral to Saipem’s medium-to-long term strategy, the cornerstone of which is the universal automation of offshore systems in the name of optimizing the environmental and economic efficiency of at-sea activities, as well as the digitization of critical data and information.

This story was originally featured in ON&T Magazine's November/December 2021 issue. Click here to read more.