Seanic: An Interview With Seanic President, Tom Ayars

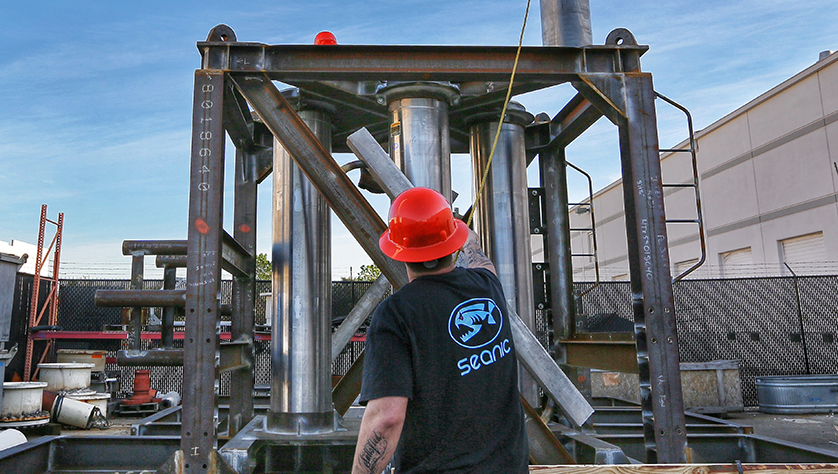

Founded in 2007, Seanic Ocean Systems is currently headquartered in Katy, Texas. In 2016, the company completed a state-of-the-art facility located on 10.5 acres that includes a 55,000 sq. ft building and an in-ground wet test tank where Seanic recently completed their largest full-scale in-water test to date. The 3-day test was carried out on behalf of a major operator and engineering contractor and included equipment that was designed and built by Seanic in a full-scale System Integration Test (SIT) environment.

ON&T sat down with Tom Ayars, president of Seanic, to discuss the evolution of his company and its new partnership with Underwater Engineering Services (UES).

Could you tell us a little bit about what Seanic does?

Tom Ayars: We manufacture what is commonly called intervention tooling, though I am often somewhat hesitant to use that term because we do so many other things. Another way to put it is we build products that allow ROVs to complete tasks—pretty much everything that comes between the ROV and the existing subsea hardware. When we started out, our local competition was two very large companies, and tooling was not their primary focus. So we felt that we could start a business focused on the type of projects they didn't seem to be interested in—which, in the end, is basically what ended up happening. After we recruited our VP of Operations, Andy Guinn, he and I found a little building, purchased the hand tools, computers, and furniture, and hired a couple of engineers.

In the early days, there were five of us. By the fall of 2014, Seanic grew to 60 employees. As we went through the learning curve, we were asked to perform all kinds of other design/build projects. Since that time we've built a diverse and robust product line and participated in a multitude of exciting bespoke engineering solutions. Our new facility has opened up new opportunities, and now, nearly a decade later, we've developed a whole set of competencies beyond intervention tooling.

Can you talk about those expanded skills?

Tom Ayars: Bespoke projects test you in so many ways and are often concepts that are being created for the first time. They typically include elements of deep water, high current, limited space, chemical compatibility, unique materials, a fast-paced schedule, and a host of other things that have to be considered when thinking through what the final product will look like. If you're going excel in this business your engineers have to be creative, fast, accurate, and constantly honing those skills. This is something our engineering team has excelled at, and it's reflected in the unique products we've built over the years. Examples would be our Flex Joint Inspection Tool (FJT) and a unique ROV, operated subsea water blasting system (ECB) that incorporates cavitation technology.

How does the flex joint inspection tool work?

Tom Ayars: Flex joints are subjected to extreme conditions, and any associated downtime can cost operators time and money, so it's important that they be inspected and maintained. Operators tell us that a planned maintenance to change out a flex joint can cost in the tens of millions.

To help operators manage future cost, Seanic developed a tool that has gained popularity as operators want to assess the status of their flex joint and determine the potential life of this very critical component. The FJT is attached by an ROV to a dynamic riser right under a flex joint; it provides a stable platform to safely and effectively clean the marine growth that covers the elastomer rubber. Once cleaning operations are complete we install the inspection package which gathers detailed images that can be used to produce 3D models that allow for future detailed analysis. If an anomaly is detected, this process allows operators to generate a baseline and then track that anomaly over time to evaluate if any further actions need to take place.

How does the subsea water blasting tool work?

Tom Ayars: The ECB is based on cavitation water blasting. It was originally developed to clean marine growth off strakes and fairings, which are used on subsea risers and are often somewhat soft and made from a lightweight material. Over time, they become encrusted with marine growth and require cleaning. If you use a typical 5K water blaster, it won't effectively clean the material. If you use a 10K water blaster, the material has the potential to be damaged.

We came up with a concept that repackaged a proven technology that has been around for a long time. Divers have used cavitation blasting for years; it's basically a high volume of low pressure water flow. Coupled with a cavitation nozzle, this type of blasting has more of a pulsating effect vs. just sheer pounding with high pressure. Basically, we took standard triplex pumps and marinized them so they can be mounted directly to an ROV giving us an effective way to clean these soft materials. Over the years, our ECB has become the industry standard for projects of this type.

Your parent company, Centurion Group, recently merged with ATR Group to create a global player in the oil and gas rental equipment and services market. Underwater Engineering Services (UES) was a division of ATR Group specializing in the supply of marine and subsea support equipment within the offshore energy industries. Can you talk about that partnership with the Aberdeen-based company UES and what that can bring to the table?

Tom Ayars: Seanic and UES are joining forces. UES has always been more focused on deck equipment and standard tools in support of the diving industry, so they haven't typically participated in what you would call ultra deep water.

Seanic, on the other hand, has been all about deep water in support of ROVs, so working together seems to be a natural fit. The ability to share people, equipment, and capabilities to provide like services in both the Gulf of Mexico and Aberdeen is not only exciting, but I think it will be well received by our mutual clients.

It sounds like you will now be able to offer services throughout the entire water column by bringing these two companies together, since UES is working in depths conducive to dive operations and Seanic works in much deeper depths.

Tom Ayars: Absolutely. The two companies complement each other very well, and it really won't take much time to cross-pollinate our skills. Going forward, we will collectively market the reliable products and services we've been known for over the years. Aberdeen is a big hub for world-class vessels that sail all over the world to perform oil industry projects. So, between the Gulf of Mexico and Aberdeen, we can effectively serve two of the biggest markets in the world.

For more information about Seanic, visit www.seanicusa.com.