Subsea Battery Solutions for Large Energy Storage

Over the last ten years, SubCtech has earned a reputation for responding to the shifting demands for power and increasing capacity within the subsea sector.

The company’s latest response is a new series of Li-Ion batteries designed specifically for large subsea energy storage facilities, vehicle propulsion and, last but not least, for the electrification of oil and gas production locations, hence playing an instrumental role in the transition from electrohydraulic to all-electric systems.

The overarching goal is to make the global energy supply more reliable while, at the same time, minimizing the down time of production by providing sufficient uninterruptible power supplies (UPSs), and thus enabling the use of all-electric systems. This allows for very deep as well as extremely remote production facilities as it simplifies the challenges associated with long-distance tiebacks significantly.

FIRST ESS OF ITS KIND

In full support of this sector-wide mission, SubCtech is proud to release the first fully qualified (TRL 4) subsea Energy Storage System (ESS) of its kind! The SubCtech team has fully completed the production of the ESS and is in the process of completing the E/FAT, followed directly by the final SIT (system integration test).

Following the testing phase, the next milestone will be to see the full subsea operation of the approved system, with a total energy storage capacity of 2 MWh!

The growing demand for custom solutions from the offshore oil and gas industry has triggered the development of extremely reliable batteries with an expected lifetime of 25 years. With the UN T38.3, DNV-GL or API17F and MIL-STD standards and qualifications, and depending on the target market, batteries need to be able to operate in and withstand extreme conditions, and so are subject to a series of stress tests, including response to rapid temperature change, extreme vibrations, and extensive shock. Such technical assurances are essential for successful and failproof operational reliability in both shallow and deep waters. If compromised in any way, additional service interventions—or worse still, system failures—commonly incur considerable costs, both in terms of direct cost and downtime.

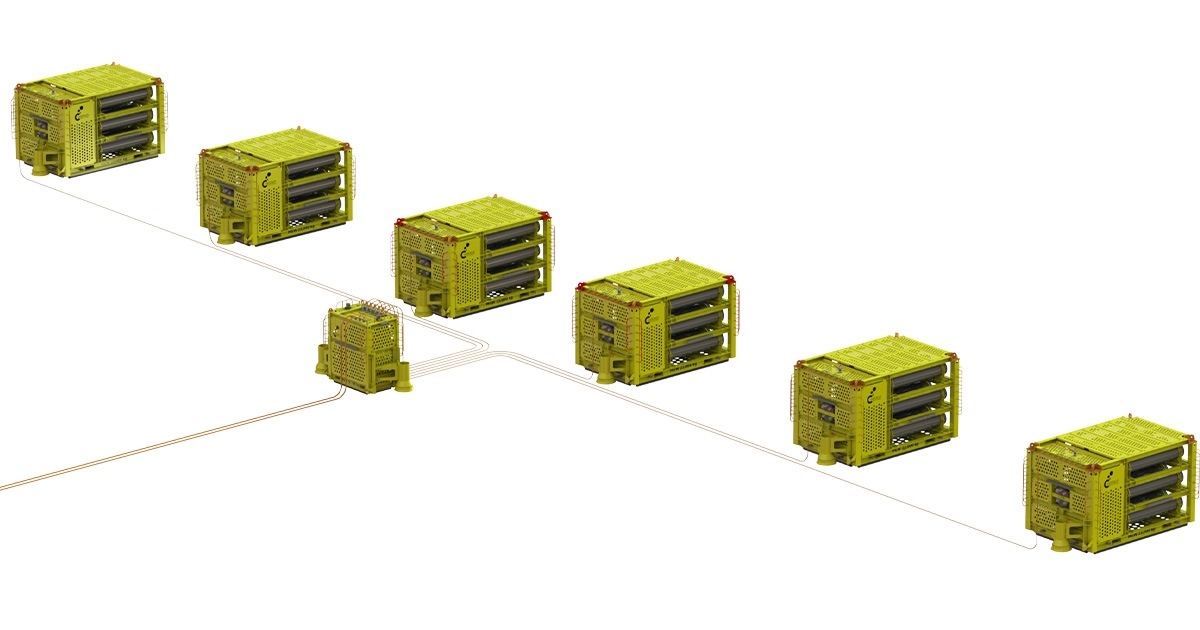

The new 1 MWh battery systems (2 of them being deployed to provide the total of the above mentioned 2MWh) are based on the well-established 100 kWh vehicle batteries, which are qualified according to different standards, e.g., MIL-STD. The Battery Control Module is based on our NetDI® Control technology. The 1 MWh battery systems can also be used as XXL AUV vehicle batteries.

The energy of the batteries is easily scalable by stacking our SmartPowerBlock™ (SPB) battery modules. Power Distribution Units (PDU), voltage conversions, as well as data interfaces, can be added into titanium or duplex steel housings as required, completing the battery system.

Our proven Li-Ion cell technology offers enormous advantages in terms of safety, energy, and power density at moderate APEX and lowest possible APEX costs. Due to the flexible design, the charger can be external/topside or can be integrated into the pressure housing, e.g., for AUV/ROV docking stations or subsea storage/UPS—both already with TRL 7. SubCtech uses high power DC and AC converters that enable short charging times without the need for complex cooling systems.

VALUE PROPOSITION

As new technologies thrust developers further offshore and into deeper waters to responsibly leverage ocean resources, never has there been more urgency to prioritize the safe and sustainable operating procedures designed to protect and preserve the oceans in the long run.

With our standardized, safe, and reliable Li-Ion batteries—guaranteed to deliver the longest possible design life—SubCtech’s solutions continue to make underwater energy reliable and cost-effective. With maintenance measures effectively minimalized, so is OPEX. Further, unlike relying on duplex or 316L steel canisters, SubCtech specializes in titanium. As a result, coating and corrosion protection (CP) is not required and this reduces the risk of pollutants escaping and contaminating the surrounding water. Since titanium housings do not require any specific servicing during their entire design life, the expense associated with regular ROV inspections can be avoided. Our Li-Ion batteries have a typical service life of 15–25 years, depending on the cell chemistry. Again, this not only reduces the need for unforeseen subsea interventions, but this extended timeframe helps with future planning and budgeting.

The fact that SubCtech manufactures the titanium housings means that battery systems can be easily scaled up to meet any special water depth and form-factor requirements.

The ability to adjust the system’s operating parameters remotely, without the need to retrieve the batteries for servicing, further reduces costs. Of course, cybersecurity has been considered and measures have been taken.

THE FUTURE

The benefit of SubCtech's All-Electric Systems technology is globally available, not only for the offshore oil and gas industry but also to fuel subsea monitoring and inspection activities, namely the autonomous underwater vehicles and their respective docking stations. The All-Electric Systems offer cost advantages compared to conventional systems, simplify service and maintenance. As an industrial standard, that would add significant value to oil and gas production facilities especially when including long-distance tiebacks or CCS applications.

For the future global market, the team at SubCtech not only see huge opportunities to expand underwater energy generation but also in the steady integration of autonomous vehicles being used to protect, preserve, and exploit our assets (ranging from critical underwater infrastructure to energy production and nature). This is, ultimately, a safer way for the ocean community to meet future challenges whilst also ensuring that we collective curb any associated costs, be them financial or societal.

This story was originally featured in ON&T Magazine's October/November 2023 issue. Click here to read more.