April: Going Deep... With Fully-Integrated ROV Solutions

BY: Stepinoff And Associates

There is something magical about the mystery of the ocean depths and the sophisticated technology, skill, navigational nuances, and logistical magic that all come into play as ROVs travel under water, often in hostile environments.

Delta SubSea provides a range of ROV services and turnkey integrated solutions that are Best-In-Class for its customers all over the world. The company has three distinct business units — ROV Services, Consulting & Engineering, and Tooling Solutions — and its specialists in the offshore energy industry are successfully tackling deepwater assignments around the world.

Heritage, Vision, Philosophy

Delta Marine Technologies, Inc., founded in 2004 as an international project management and service provider to the world’s offshore energy industry, is the predecessor of Delta SubSea.

“Our philosophy today is simple,” says Scott Dingman, president and CEO of Delta SubSea. “We treat our customers the way we want to be treated. We make sure we deliver to each and every customer our highest level of expertise, cost efficiencies, quality, promptness, and our highly trained global personnel who keep safety a top priority.”

In addition to Scott Dingman, management team members are Matthew Muddiman, chief financial officer; Jim Wagner, executive vice president of consulting and engineering; Michael Herrin, commercial manager; Alessandro Vagata, vice president of tooling solutions; and Pat Gluk, general manager.

Delta SubSea, headquartered in Montgomery, Texas, has global centers in Europe (Belgium), Trinidad & Tobago, and Saudi Arabia to support its customers. Working with its customers to meet their needs, Delta SubSea puts its vision into practice: • Our work ethic and reliability; • Our quality and safety performance; • Our values of honesty and integrity are hallmarks of our people; and • Our “can do” attitude.

Assets to Count On

Experienced, seasoned, professional, and responsive crews are the foundation of Delta Subsea’s customer commitment. “Many companies like to say that people are their best asset,” explains Dingman, “but we are unique because our employees are ‘shareholders’ so they do indeed have the company and its customers’ best interests at heart.”

This pride of ownership shows in how employees take care of the equipment, how they work with a customer to find the best solution, and how they adhere to the highest safety standards. “When our ROV operators own a piece of the equipment they are operating and maintaining, we have learned they have a vested interested in ensuring it is in peak condition,” he adds.

“Our philosophy is simple,” says Scott Dingman, president and CEO of Delta SubSea.

“We treat our clients the way we want to be treated. We make sure we deliver to each and every client our highest level of expertise,cost efficiencies, quality, promptness,

and our highly trained global personnel who keep safety a top priority.”

Manufacturing Partner

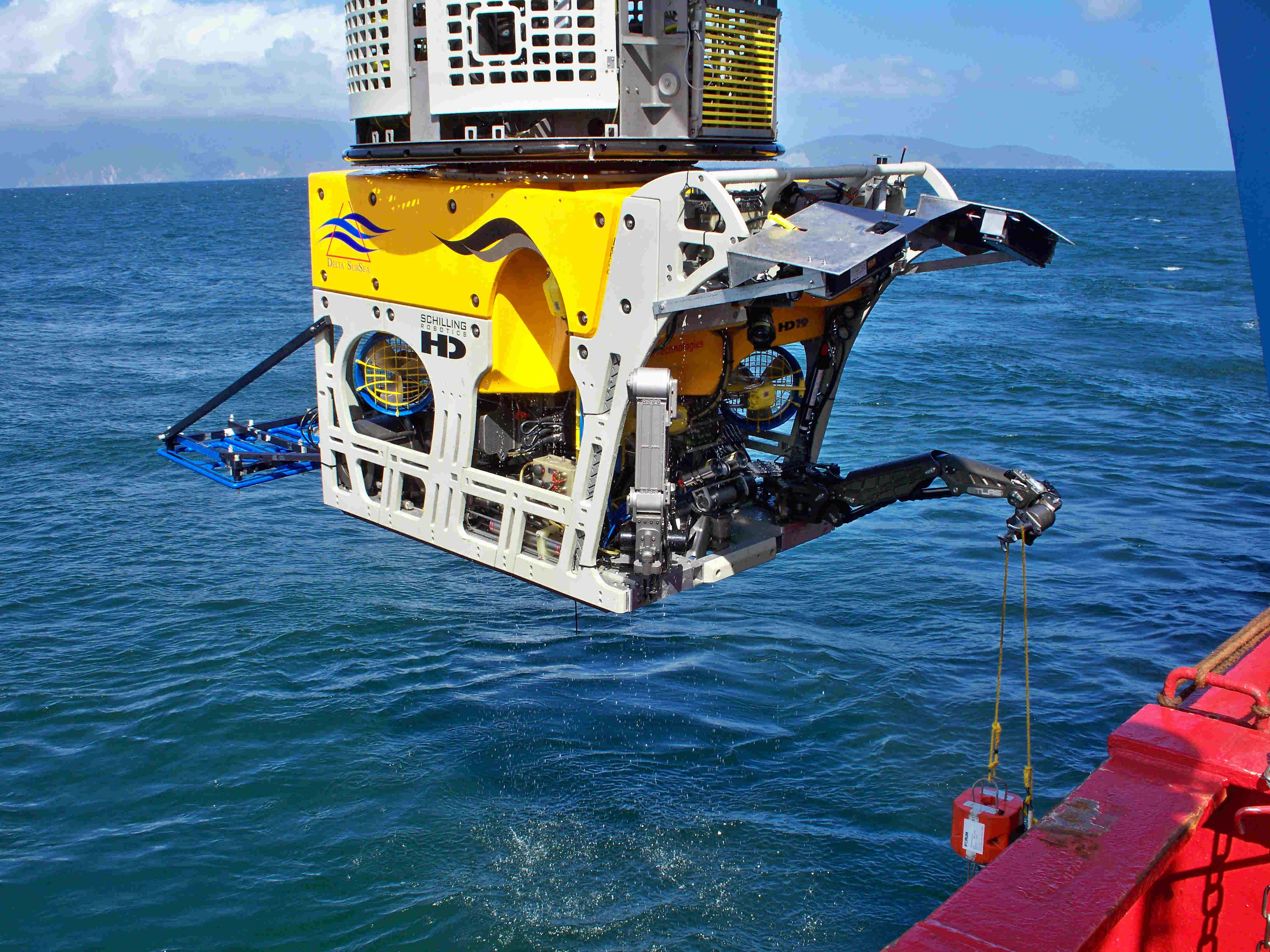

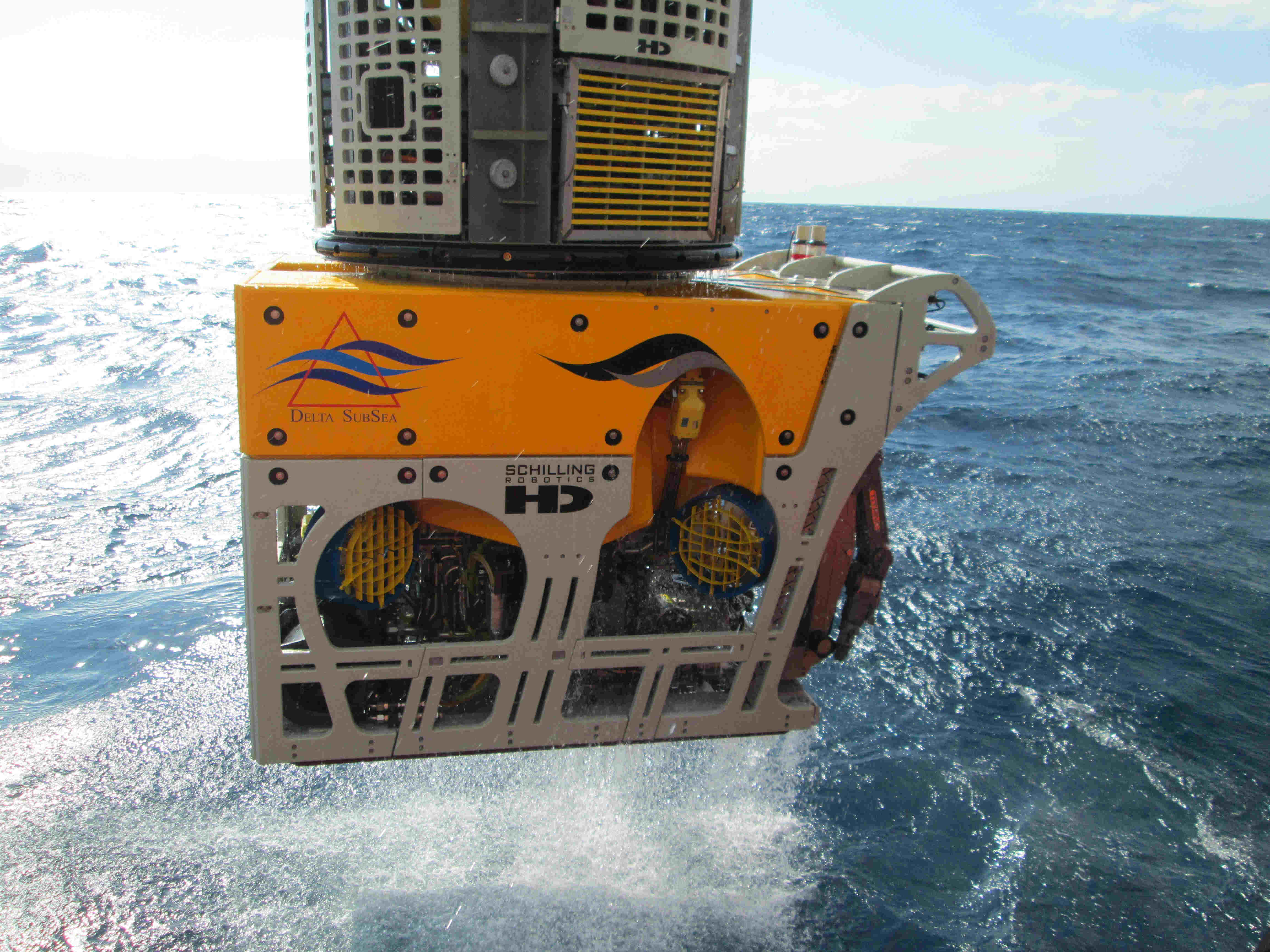

Delta SubSea’s partnership with FMC Schilling Robotics ensures its ROV division will leverage Best- In-Class equipment, highly trained and experienced personnel, and responsive and reliable technical support to deliver the industry’s highest uptime.

The Schilling team strengthens the partnership with Delta SubSea through its equipment, training, and worldwide support. With the quality of the equipment, the spares inventory, distribution centers, training center, and under-one-hour repair philosophy/replacement of most ROV components, the partnership maximizes the customer commitment Delta SubSea embraces.

Delta SubSea also has “key” relationships with Forum Energy Technologies’ Dynacon for LARS, TE Connectivity for umbilicals, Nexan for tethers, and Konsberg for cameras and sonars.

ROV Services and Solutions

Delta SubSea’s ROV services business unit focuses on the inspection, repair, maintenance, construction, drilling, and decommissioning market segments. These solutions enhance productivity in the most challenging subsea environments.

The HD™ (Heavy Duty) 150-HP vehicle is for a broader range of capabilities, providing a multi-level platform for use in the drill support and IMR segments. Also, it offers heavyduty capabilities in the construction operations.

The new UHD3 250-HP will maximize offshore productivity with 60-min service and repair, 150-HP fluid intervention, HD video system, tool dynamic positioning, and workflow centric Graphic User Interface (GUI).

Consulting and Engineering Solutions

Delta SubSea’s consulting and engineering business unit provides engineering capabilities for custom solutions. The company’s knowledgeable personnel expertly perform all phases of a project from design to execution, including project and contract management, pipeline installation lead, umbilical installation lead, manifold/structures installation lead, and pre-commissioning lead. Delta SubSea’s consulting and engineering solutions group includes cost tracking on projects, project engineers, field engineers, and fabrication oversight.

Unique Tooling Solutions

Delta SubSea’s tooling solutions business unit is emerging as a leading provider of remote technology solutions for conventional offshore subsea and deepwater developments in the oil and gas industry, with expertise in ROV, remote intervention systems, and subsea robotics. Capabilities include engineering, manufacturing, testing, service, and operations of pipeline repair systems, ROV intervention skids, ROV special tooling, and custom equipment designed to perform special subsea operations. Engineering expertise includes subsea “Our philosophy is simple,” says Scott Dingman, president and CEO of Delta SubSea. “We treat our clients the way we want to be treated. We make sure we deliver to each and every client our highest level of expertise, cost efficiencies, quality, promptness, and our highly trained global personnel who keep safety a top priority.” Ocean News & Technology April 2014 24 operations, electrical and mechanical engineering, hydraulic design, structural design, FEA, control systems, HMI, and PCB design.

Delta SubSea’s unique “Tool Pool” offers a competitive advantage because it enables customers to save money by renting out the equipment they previously purchased. This “value added” service gives Delta SubSea and its customers the opportunity to share a profit with the equipment when they are not using it.

One of Delta SubSea’s core business values is a health, safety, and environment (HSE) philosophy that translates into a commitment to adhere to strong HSE principles.

For the offshore industry in general, and specifically the ROV operational segment, there are regulations, legislation, and standards that are required to be met by all offshore companies. As a leading company, Delta SubSea has its own training centers, ROV pools, ROV simulators, personal development plans, and a competency program to ensure its personnel are prepared to safely work in the challenging offshore environment. The basic offshore training components emphasize safety while to, from, and on a vessel and a platform and specifics such as fire safety, first aid, and helicopter emergency escape.

Because of the evolving technological sophistication of subsea systems, technical training is key to effectively operate ROVs. For example, ROV pilot technicians must develop technical expertise to maintain, inspect, and operate ROV systems and associated equipment. An employee can achieve a Proof of Competency certification, proving the individual has gained knowledge, skills, ability, experience, and training in a particular role.

Delta SubSea provides its ROV pilot technicians with a logbook to record specifics such as operating hours, offshore assessments, and tooling hours. These elements support competency guidelines for pilot technicians as well as supervisors and superintendents. Simulators are used to train pilot technicians on land before they work offshore. This training saves customers time and costs.

Major International Certifications

Delta SubSea has achieved several major certifications: ISO 9001, ISO 14001, and OHSAS 18001. The ISO 9001 group focuses on quality management and contains many of ISO’s best-known standards that ensure a company’s products and services consistently meet customers’ requirements and that quality improvement is ongoing. The ISO 14001 family establishes criteria for an environmental management system that includes assurances that environmental impact is being measured and improved. OHSAS 18001 (Occupational Health and Safety Advisory Services) is a British Standard for occupational health and safety management systems. Delta SubSea also is AMPCO certified, referring to the safety tools that comply with recommended international safety standards.

Delta SubSea takes pride in meeting the stringent requirements of its customers all over the world. A major E&P client challenge was to have urgent Inspection Maintenance and Repair (IMR) work completed on its deepwater gas production infrastructure off the coast of Trinidad & Tobago. The E&P client immediately needed an ROV and a team to visually inspect the infrastructure as well as implement repair and maintenance. Delta SubSea’s team deployed at 12:01 AM, the day after signing the contract, and drew on its long operating history in Trinidad & Tobago to efficiently deploy in-country on an expedited basis.

When BP US needed subject matter experts in diving/ROV/subsea construction to provide oversight on BPleased IMR vessels in the U.S. Gulf of Mexico, Delta SubSea had the perfect solutions. Successfully meeting all of the complex requirements from logistics to security, Delta Subsea provided qualified, competent, and experienced leadership to the project.

Delta SubSea’s expertise in HSE was valued when EMAS AMC required an offshore HSE coordinator/medic. Delta SubSea provided HSE leadership and training on various owned and contracted vessels in the Gulf of Mexico, West Africa, North Sea, and Norway.

its total integrated turnkey solutions are Best-In-Class, the company weaves its magic to build the world’s largest — and best — deepwater ROV fully integrated solutions provider.

Call Delta SubSea to unlock the mystery of how it can provide a world of solutions at all levels for the life of your project (936 582-7237).