Advanced Inspection-Class Underwater Robots for Offshore Energy Inspections

The underwater inspection of marine equipment and subsea assets can be challenging and expensive. Traditional work-class vehicles, while larger, are not always the best solution for conducting offshore missions.

Instead, inspection-class underwater robotic systems can offer a safer, easier and more cost-effective option. However, not all systems of this size are robust enough to withstand harsh oceanic conditions, so choosing a system with an established record of success and durability is important.

VideoRay Mission Specialist underwater robots are an excellent choice for offshore inspections. They are designed to carry heavy payloads and tools while navigating tight spaces that larger work-class vehicles cannot access.

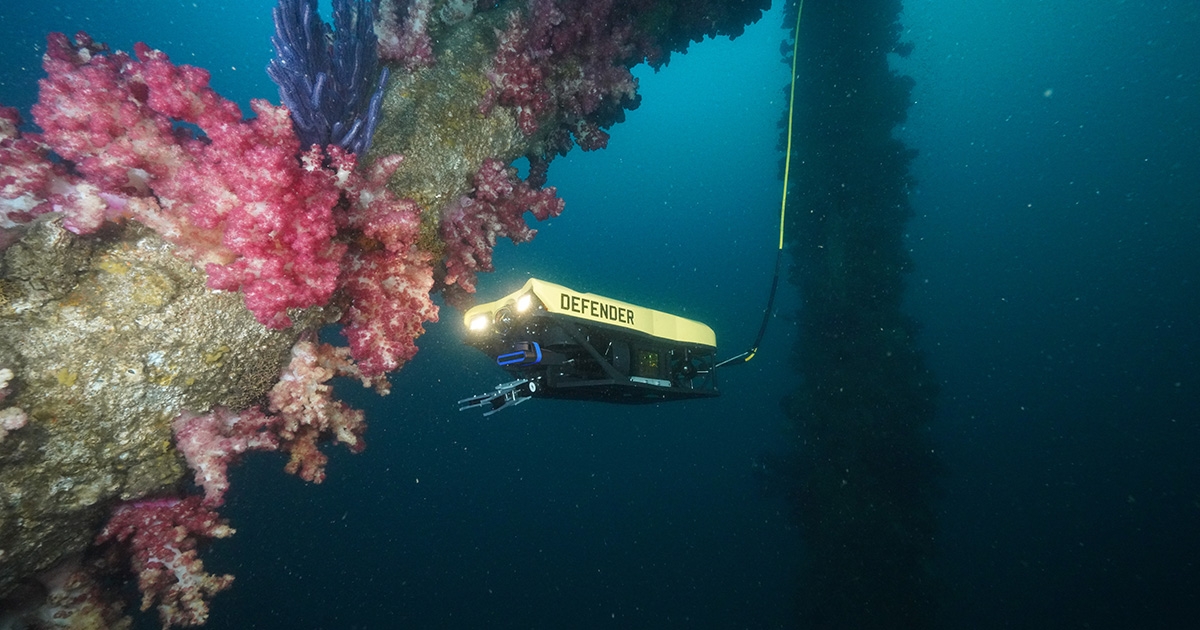

For example, the Mission Specialist Defender system boasts seven powerful thrusters that can handle currents up to four knots and has a 1,000-meter depth rating. This makes it ideal for precise control, heavier payloads, lifting, and specialized operations. It can move in any direction and maintain active pitch to move the vehicle upward or downward.

The Mission Specialist Pro 5 system, with three thrusters and a 305-meter depth rating, is designed for speed, efficiency and portability and is perfect for missions with size, space, weight, and deployment speed constraints.

VideoRay Mission Specialist systems can be equipped with Greensea navigation, control, autonomy and user interface technologies. The advanced, user-friendly vehicle control system provides exceptional stability and maneuverability for complex tasks. With multimode control, the vehicle can operate at a high level of autonomy, enabling the pilot to focus on the intricacies of the mission.

Large and small energy production operations worldwide trust VideoRay underwater robotic systems for at-sea missions. Here are three case studies that exemplify the broad utility of our multipurpose platforms:

PROCEANIC

The first success story comes from the Proceanic Group of Companies, a full-service engineering, project management and underwater robotic inspection company based in Houston, Texas, with offices in Singapore, Malaysia, and Brazil. Over the past ten years, the company has purchased multiple VideoRay Mission Specialist inspection-class underwater robotic systems to support its base business operations and expand its reach.

Proceanic works extensively in the South Atlantic Ocean West Africa region, the Gulf of Mexico, Brazil, and Southeast Asia, where they need underwater robotic systems that perform well in extreme conditions. For over a decade, Proceanic operators have relied on VideoRay's Mission Specialist Defender and Pro 5 systems, both of which have provided the reliability and robustness required in a marine environment. These systems are adaptable and flexible, allowing personnel to integrate and upgrade the tooling in the field easily.

In addition to being a key customer, Proceanic is a valued partner and serves as an authorized VideoRay service center on the US Gulf Coast. Over the last decade, Proceanic has completed more than 200 complex offshore subsea campaigns, including inspecting the world’s largest floating production storage and offloading (FPSO) vessel.

OCEANEERING

The second case study comes from Oceaneering International, a global subsea engineering company headquartered in Houston, Texas. Michael Johnson, Program Manager of International Diving Programs at Oceaneering, needed a rugged underwater robotic system that his team could easily carry onto a vessel, deploy and use to inspect and clean ships. The offshore support vessel (OSV) was located in the southern Atlantic Ocean off the coast of Angola, and the Oceaneering team needed an underwater robotic system that could handle difficult subsea environments, transport easily to locations around the world, require only one operator, maneuver in confined spaces, and accommodate specific probes and cleaning tools.

After evaluating the Mission Specialist Defender system, the Oceaneering team recognized how easy it is to integrate accessories onto the rugged Defender system for reliable operation in harsh environments offshore. During the project, they recorded vessel inspection images and easily transferred them to Oceaneering management locations.

Oceaneering was impressed with the portability and low overall weight of the Mission Specialist Defender system. The company now has a dependable underwater robotic system on its vessel off the coast of Angola that personnel can easily transport anywhere in the world. The Oceaneering team uses the Defender system to inspect vessels, including required testing using a cathodic protection probe and cavitation cleaning using a cavitation cleaning tool.

CSPECT

The final installment in this three-part demonstration of the real-world application of advanced subsea robotics comes from CSpect, a company that specializes in the inspection of offshore wind monopile and wind turbine foundations in the North Sea, and so services the largest global renewable energy contractors in the world. Headquartered in Belgium, CSpect sought a mobile solution to conduct wind turbine jacket inspections without the need for a larger work-class vehicle and an entire crew onboard an OSV. CSpect partnered with VideoRay to develop a cost-effective way to provide underwater inspection of wind monopiles to the North Sea wind farms marketplace.

The robot’s weight and maneuverability are key to performing monopile inspections while reducing cost. Operators can drop the durable Mission Specialist submersibles into the water from the monopile, making it less expensive than using work-class vehicles. There is no need for an OSV, A-frame, crane, or additional personnel.

CSpect used a combination of the VideoRay Defender and Pro 5 systems, coupled with its own engineered tooling, to conduct comprehensive inspections of wind turbine jackets. By eliminating the need for larger work-class systems and teams onboard an OSV, CSpect has reduced costs by more than 50%, decreased inspection time by more than 50% and improved safety by eliminating the need for a shipboard team. Also, because no OSV was deployed, CSpect reduced the overall carbon footprint of the mission to near zero.

REDEFINING SUBSEA INSPECTIONS

At VideoRay, our mission is to redefine subsea inspections by developing underwater robotic systems that are ready to perform critical jobs in the harshest marine environments. Much more than underwater cameras, VideoRay’s inspection-class systems deliver industry-leading power and maneuverability, enabling operations in currents up to four knots. The durable modular platform is built to handle heavy payloads and a wide array of sensors and tooling. And they can operate at significant depths for hours, days or even months at a time.

VideoRay Mission Specialist robots are rugged enough to work anywhere, handling tough jobs and applications. They are used around the world in demanding underwater missions to support national security, first responders, object search and recovery, infrastructure examination, and science and research.

Mission Specialist systems are designed to support new ways of working at sea by offering unmanned solutions that greatly reduce—if not eliminate—human dive time in hazardous conditions. By packing the power and functionality expected from larger, more expensive systems into a form factor that is sized just right, VideoRay’s inspection-class robots bring a new dimension and utility to portable, one-man deployable marine robotics designed to significantly reduce costs while streamlining logistics.

To find out more, visit videoray.com or call +1 610-458-3000.

To read the full article, which was featured in ON&T March 2023, click here.