Project Recover Relies on ADL Embedded Solutions to Get the Job Done

Finding Answers

Mysterious oceanic disappearances have occurred throughout history - missing ships, aircraft, and submarines, there are many open-ended questions. Finding the answers to the myriad of questions a disappearance creates is the mission of Project Recover, a nonprofit organization dedicated to bringing America’s missing in action (MIAs) home. The Scripps Institute of Oceanography, part of University of California San Diego, participates in Project Recover and is a proud client of ADL Embedded Solutions (ADLES).

What is Involved in the Search Mission?

Searching for lost objects in the deep ocean is a tedious and challenging task. Image courtesy: Pixabay

Project Recover underwater search missions are typically four to eight hours but can last to as much as a full day. To increase operational efficiency, the Scripps Institute of Oceanography deploys ADLES’ embedded computer products to capture relevant data in the deep ocean. In the data acquisition process, the SBC performs multiple tasks including sensing, reacting to that intelligence and modifying behavior. The ADLES embedded system uses artificial intelligence (AI) to make local decisions.

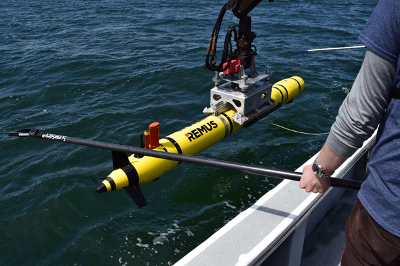

The Scripps Institute of Oceanography, part of the University of California San Diego, is based in La Jolla, California. The institution searches for lost objects worldwide connected through satellite communication. Image courtesy: Tech Idea Research

The Scripps Institute of Oceanography has established the following search mission processes:

- Define a specific area in the ocean to be searched.

- Search using Unmanned Underwater Vehicle (UUV) technology as the primary source of information acquisition for the mission.

- Collect data employing an ADLES embedded solution equipped with multiple sensors.

- Use wireless communication between the land-based unit and the UUV.

- The communication methods include using acoustic modems, hydro telephone, and Wi-Fi if the UUV is close enough to the shore.

- Satellite communication is used when the UUV comes to the surface and/or for emergency purposes.

- Use artificial intelligence for data capture and its initial processing.

- Data download for post-mission data analysis can be done via Wi-Fi, or a Gigabit Ethernet cable, depending on the volume of data.

- Perform post-mission data analysis.

REMUS model 100 is an Unmanned Underwater Vehicle (UUV) used by the Scripps Institute of Oceanography to conduct searches. Image courtesy: Hydroid

System Requirements

The Scripps Institute of Oceanography uses the REMUS model 100 and 600 UUVs equipped with the ADLES’ 3800PC SBC (ADLE3800PC) to capture data. If the embedded computer discovers interesting data during a routine search, it has the capability of guiding the UUV to the new location thus deviating from the preprogrammed route.

The ADLE3800PC-based embedded system has the versatility to capture data from multiple sensor types, including:

- Magnetometer – operates similarly to a metal detector to discover the ships buried under the sand in the ocean

- Sonar

- Forward-looking sonar

- Multi-beam sonar

- Still image camera

- Acoustic sensor

Because the UUVs operate in a remote, rugged environment, their embedded electronics, including those of their embedded computers, must exceed commercial-grade performance. Power conservation while delivering multi-core CPU performance is crucial. The overall embedded SBC requirements are:

- Multi-core processing capability with on-demand use.

- When system performance is not needed, the SBC can be put in a sleep or idle mode to conserve power.

- Ample I/O slots, including serial and Ethernet, to collect data using multiple sensors.

- Compatible small footprint to the system’s original PC/104 design to obtain a drop-in-place solution.

- Able to operate reliably over a wide temperature range and to withstand heavy shock and vibration.

- Long product lifecycle support.

- Easy to implement within a reasonable budget.

ADLES’ Problem-Solving Approach

For mission-critical industrial applications taking place in aeronautical and underwater environments, failure is very costly. These applications demand real-time results and operational efficiency to ensure 30+ hour performance - precise power budgeting is a must.

Remote search missions also rely on AI data collection to take place without needing guidance from a land-based system. System performance delays or hardware failures may mean lost opportunities and the risk of a costly mission repeat.

Rugged applications require the continuous collection, processing, and storage of data in environments that are often remote and hostile. In addition, the SBC must adhere strictly to space, weight, and power (SWaP) requirements. Overall operation success rides on how well the SBC integrates data sets and interoperates with other systems. Reliability and ease of maintenance are key.

ADLES’ solutions provide high-performance, compact, system-criticial grade SBCs. ADLES believes that achieving effective solutions for its clients demands holistic embedded solutions that go far beyond just hardware - a deep understanding of customer needs is a must.

Designing an embedded solutions is a complex process requiring engineering teams specializing in:

- Systems

- Mechanical

- Thermal

- Electrical

- Cabling

- Software

- Prototyping

- Testing

- Quality Control, and

- Production

ADLES’ years of experience in the rugged and embedded industry make us a leader in designing and delivery rugged, small form factor and extreme environment solutions based on our customers’ individual specification needs.

The Results

The Scripps Institute of Oceanography search for a hardware solution fully up to Project Recover demands required ADL Embedded Solutions’ 3800PC SBC. A major factor in the selection was ADLES’ 25+ year reputation for product quality and reliability.

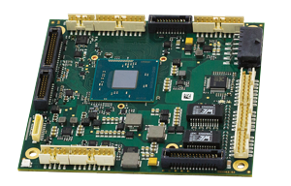

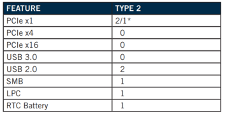

Based on the Intel Atom Processor E3800 quadcore SoC processor, the ADLE3800PC PCIe/104 SBC supports Type 2 downward-stacking PCIe/104 (plug compatible with PC/104) V2.01 with 2x Gen2 PCIe x1 lanes. It runs on 5V and delivers 8W to 10W power. Image courtesy: ADLES

The ADLE3800PC PCIe/104 form factor (90 mm x 96 mm) SBC is designed to support unmanned systems operating in rugged environments and is I/O plug compatible with the PC/104 requested by SCRIPPS. It is equipped to power drone payload computing, rugged surveillance cameras, and Azure cloud-based IoT solutions. Based on the Intel Atom E3800 quadcore SoC processor, the SBC supports Type 2 downward-stacking PCIe/104 configuration running on 5V and consuming only 8W to 10W power.

Multiple I/O ports make highly flexible design support a key ADLE3800PC asset:

- 2x SATA 3 Gb/s; Shared with mSATA Socket

- 2x 10/100/1000 Mbit Ethernet LAN Port; Intel i210 [missing words?]

- 2x RS-232 COM Ports

- 8x USB 2.0 Total, 4x USB 2.0 Pin Connector, 2x PCIe Connector, 1x Mini PCIe

- Socket, 1x USB 3.0 (Backward Compatible to USB 2.0)

- 1x USB 3.0

The ADLSST System Sensor Technology v2.0 utility, which runs on Linux, is available to ensure that the SBC, including the I/O ports, performs according to specification.

The SBC is designed specifically for applications in rugged environments. Its extended temperature range is from -40 oC to +85 oC. The ADLE3800PC SBC meets stringent size, weight, and power (SWaP) requirements. It also boasts a fifteen-year lifecycle support with availability through 2030.

The Scripps Institute of Oceanography trusts the ADL3800PC SBC product quality, performance, and reliability. Moving forward, the Scripps Institute of Oceanography will develop additional AI software for autonomous target reacquisition, increasing the ADLES SBC’s target detection strengths even further.

How ADL Embedded Solutions Can Help You with Your System Design

ADLES is eager to assist your engineering teams with the customized system design, optimization and production of your mission critical system solutions.

Through 25+ years’ experience, ADLES has developed an in-depth understanding of our customer’s specific requirements. Assuring your success from accelerated design and development with overall cost reduction is crucial to ADLES. To accomplish that, they provide a wide range of client support. For example, ADLES can refine design concepts according to critical requirements by supplying CAD models and full-turnkey system design services. This broad spectrum of industry leading support also includes proof of concept consultation, design, prototype, pilot, quality control and production services.

ADLES provides system and thermal design expertise with a robust set of 3D design tools (SOLIDWORKS) thus accelerating design development and minimizing our customers’ time to market. ADLES works closely with metalwork, milling, coating, and component vendors. The aim is to shrink design and prototyping costs from every angle. As part of building fully integrated systems, ADLES validates the ease of integration and production while verifying electrical and compliance specifications.

About ADL Embedded Solutions, Inc.

ADLES recognizes the enormous effort it takes to design, develop, and customize an embedded system to each customer’ specific application. We want to be your partner to provide the best system solution to fit your needs. You can rely on ADLES to accelerate your design process, reduce your development costs and optimize your final product results.

Contact ADL Embedded Solutions to discuss your requirements.