The International Ocean Science & Technology Industry Association (IOSTIA) has announced a new program for its U.S.-based members aimed at providing employer members, their employees, and self-employed industry professionals a viable, cost effective, and accessible healthcare program.

Milestones

All Stories

BIRNS, Inc., an ISO 9001:2015 certified manufacturer of high- performance lighting and connector systems, announces the appointment of Abel Nemeth as Manufacturing Engineer at the company’s headquarters.

Sparrows Group is celebrating after coming out on top at the 2018 Press and Journal Gold Awards, winning the esteemed Renewables Award.

Oil and gas production optimization specialist, Enpro Subsea, has announced a new senior advisor to bolster the strategic team in the Americas as part of plans to expand market share and build portfolio in Brazil.

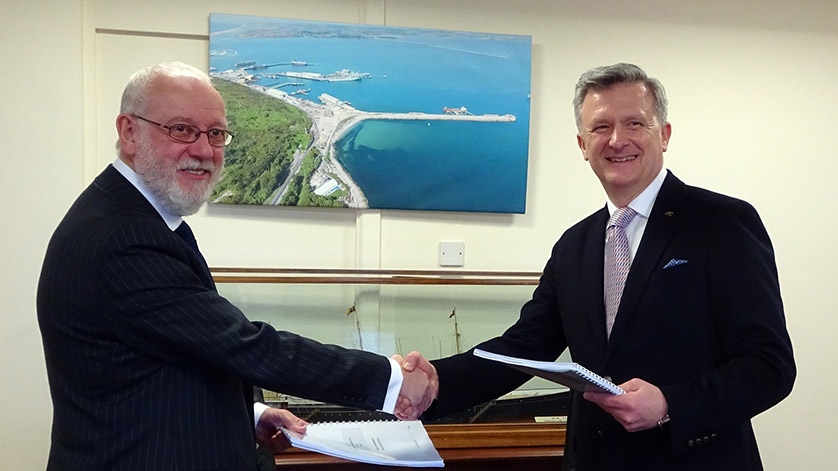

Maritime engineering company Intermarine UK has landed a contract from Cammell Laird shipyard on Merseyside to supply the £160million RRS Sir David Attenborough polar ship.

Riptide Autonomous Solution announces its first international expansion with the creation of Riptide Autonomous Solutions Canada. Headquartered in Halifax, Nova Scotia, Riptide Canada is being established to support the increasing demand in Canada and abroad for affordable, flexible AUV systems.

Paul Smith has been appointed group managing director at UTEC Survey (UTEC), one of the industry’s leading off- and onshore survey companies and part of subsea services group Acteon.

Global subsea equipment specialist, Ashtead Technology, has underlined its commitment to continued growth with the appointment of Stephen Steele as corporate development director.

Maritime safety equipment manufacturer and global service provider VIKING Life-Saving Equipment A/S has announced it has acquired Norsafe, the Norwegian boatbuilder whose lifeboats are used throughout the world. The acquisition is in line with VIKING’s long-running strategy of putting the customer’s needs and priorities first.

Unique Group, a leading integrated offshore solutions provider, has completed the acquisition of the Aberdeen headquartered, load-testing equipment provider, Water Weights.

Ørsted recently signed a six-year framework agreement with Trelleborg for the supply of NjordGuard™, a cable protection system, for use on upcoming wind farm projects.

CGG and PETRONAS Carigali Sdn Bhd (PETRONAS Carigali), a wholly-owned subsidiary of Petroliam Nasional Berhad (PETRONAS), have agreed on a collaboration to provide access to CGG’s latest technology and expertise in high-end seismic and multi-physics imaging, and reservoir characterization.

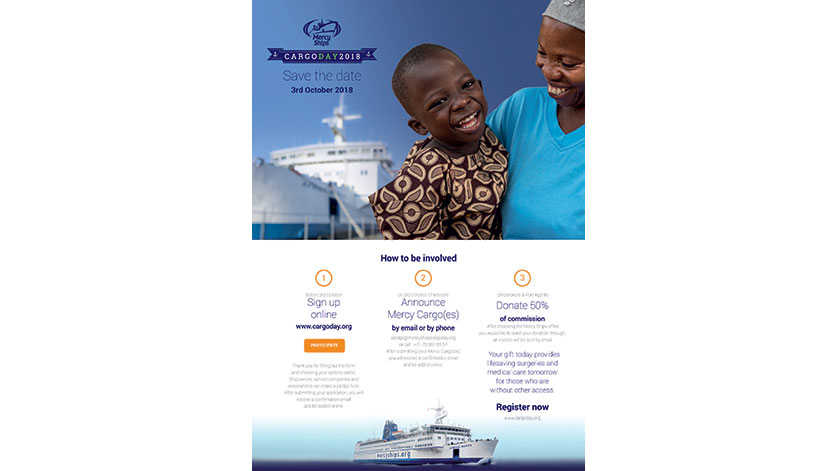

August 29, 2018: Mercy Ships Cargo Day, an annual event established by the worldwide shipping community in 2016, has announced a $1 million target goal for 2018. The event, held Oct. 3, provides the opportunity for the shipping and trading community around the world to donate 50 percent of its commission on cargoes (Mercy Cargoes) or to make a direct financial contribution to Mercy Ships.