Study Identifies Strategies for Improving Reliability of Bolts Used in Offshore Drilling Rigs

A new study from the National Academies of Sciences, Engineering, and Medicine identifies strategies for improving the reliability of bolts used in offshore oil and gas drilling rigs.

Released in June 2018, the BSEE-sponsored study aimed to determine the optimal material properties and coating requirements associated with fasteners used in critical safety components and equipment in offshore oil and natural gas subsea operations, thereby mitigating the risks of critical offshore connector equipment failures.

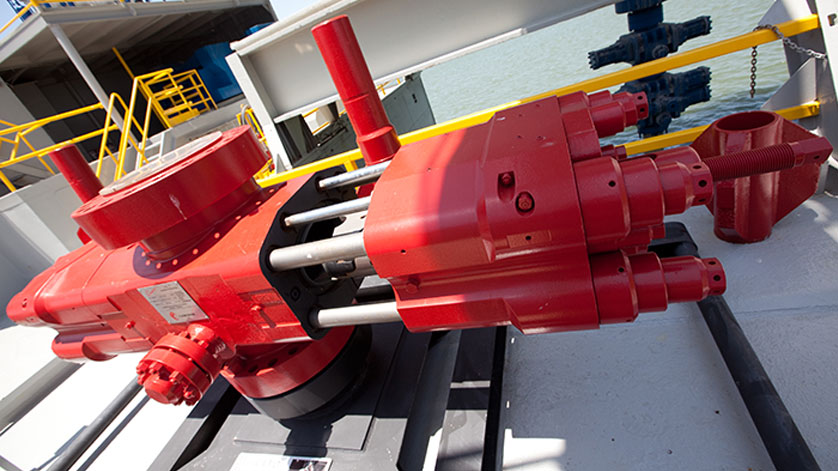

Although no major oil spills have resulted from the failure of a bolt fastener, there have been minor oil releases and near misses caused by unexpected bolt failures. The study includes a summary of selected subsea bolt failures with emphasis on those fasteners that hold together critical pieces of safety equipment, particularly blow out preventers (BOP), and those that secure the pressure boundary in risers. The role of hydrogen in embrittling fastener materials is the subject of some discussion and analysis in the study.

The study does recommend actions that BSEE should take, but it does provide a number of options that, if taken, would likely improve the reliability of subsea bolting. It also provides recommendations to the oil and gas industry that do not require regulatory action that would likely improve the reliability of subsea bolting.

The High-Performance Bolting Technology for Offshore Oil and Natural Gas Operations High-Performance Bolting Technology for Offshore Oil and Natural Gas Operations study can be ordered in print or downloaded for free here.

More information regarding BSEE’s risk mitigation efforts for bolts can be found here.