Cammell Laird and BAE Systems Showcase Leander Type 31e Frigate

Exports will be central to Cammell Laird and BAE System’s joint bid for the Government’s £1.25 billion new-build frigate program, a conference has heard.

The news was announced at a special ‘supplier conference’ organized by Cammell Laird, BAE Systems and the Society of Maritime of Industries on Merseyside involving more than 200 delegates from supply chain companies in the UK and overseas. Demand was so high that a second event for a further 100 companies has been scheduled for March 28.

The procurement process to design and build five Royal Navy T31e frigates was launched by the Government in 2017 and a key objective of the program is to attract overseas orders. Cammell Laird is bidding for the tender as prime contractor, in a teaming agreement with BAE Systems, with a warship design known as ‘Leander’. If successful it could see steel cutting beginning on Merseyside in March 2020.

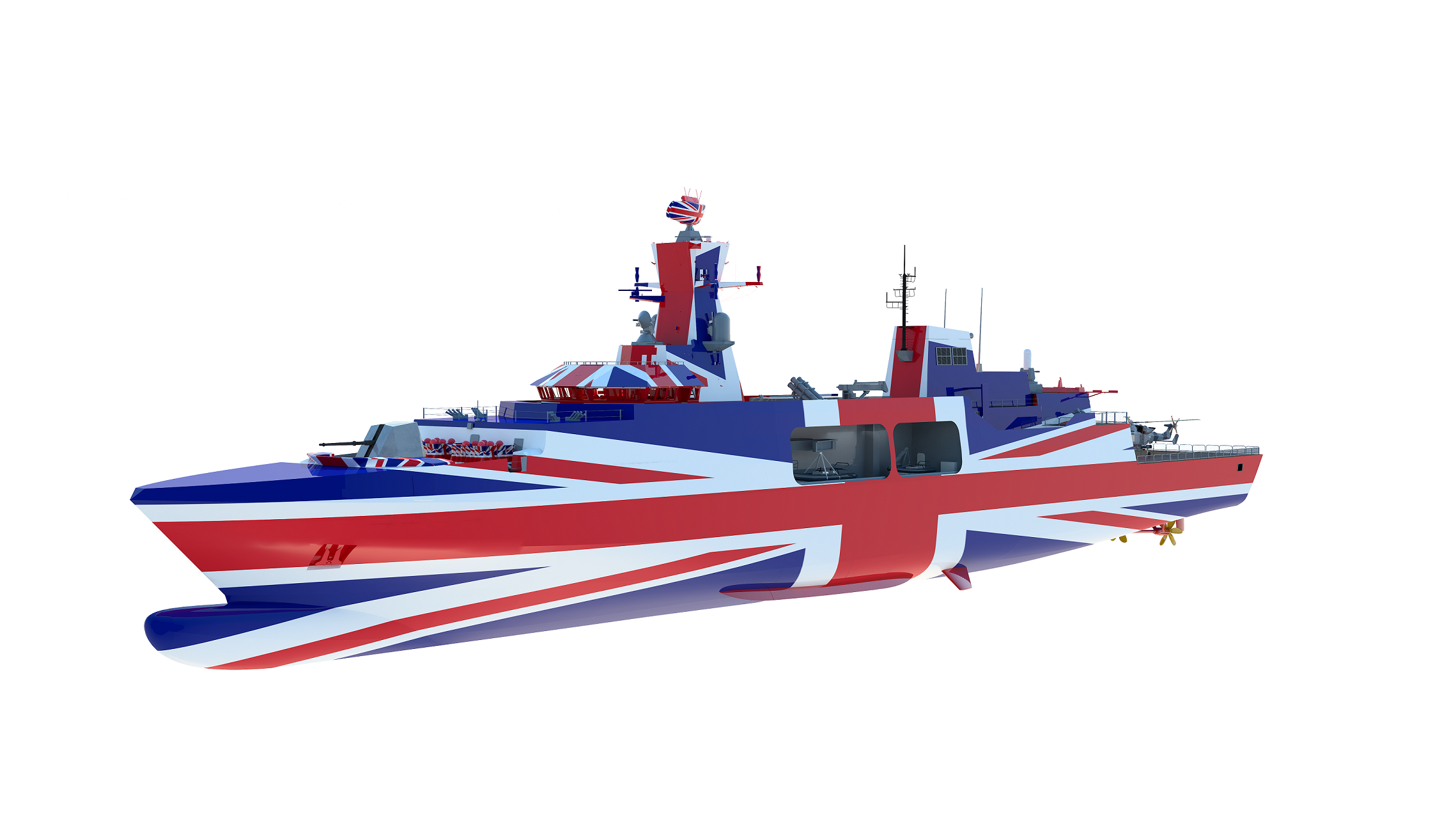

Cammell Laird BAE Systems Leander Type 31e Frigate Union Jack copyright Cammell Laird. Copyright ©2018 BAE Systems. All Rights Reserved

Cammell Laird BAE Systems Leander Type 31e Frigate Union Jack copyright Cammell Laird. Copyright ©2018 BAE Systems. All Rights Reserved

Cammell Laird’s Type 31e project director Tony Graham told the conference the £250million price tag for the ‘powerful and affordable’ Leander will excite many overseas customers, as it lays plans for a global warship exports division.

“In order to win this competition, we must be better, cheaper and faster than anyone else,” he said. “Fundamentally, we recognized that this ship has to work straight ‘out of the box’,” he said. “Leander is a very practical warship with credibility, a degree of ruggedness and robustness, and delivering low risk lifecycle costs.

“We have a global campaign plan for the Type 31e program and have identified opportunities in more than 20 countries. Our intent is to build a warship export business based on Leander. The MoD has indicated it is willing to sign a business agreement alongside the contract to help industry export the Type 31e. This joint approach between the Government and the Royal Navy producing a proper business plan for exports has never been seen before.”

Cammell Laird managing director Linton Roberts said an overwhelming response to the conference provided a strong endorsement of the aims and aspirations of the National Shipbuilding Strategy.

“We have been overwhelmed by the response to this conference, to the extent that we have had to arrange a second date to ensure that all interested companies are able to attend. I think that this level of interest is a very strong endorsement of the national shipbuilding strategy and its aims and aspirations. We at Cammell Laird are very excited by the opportunity, and specifically the design we have developed jointly with BAE Systems – which we have named Leander.

“My message to the conference is that we are open for business, open to new ideas and open to new commercial relationships. We want to hear about what they can do to help us make Leander a national and international success not only for our customer, the Royal Navy, but also for UK PLC.”

The conference heard that the MoD is expected to award the Type 31e contract in March 2019.

Cammell Laird is set to launch a Type 31e website in March 2018 and will issue further details to suppliers shortly to secure quotes before submitting a final tender in the autumn.

EXTRACTS FROM SPEECHES AT THE CAMMELL LAIRD SUPPLIERS’ CONFERENCE:

Cammell Laird’s Type 31e project director Tony Graham told the conference the £250million price tag for the ‘powerful and affordable’ Leander model will excite many overseas customers, as it lays plans for a global warship exports division.

“The Type 31e competition is a direct result of the UK Government’s new National Shipbuilding Strategy,” said Mr Graham. “In order to win this competition, we must be better, cheaper and faster than anyone else. It took nine months to identify the right design partner following national and international reviews. As a result, we selected BAE Systems as our preferred supplier for the design and combat system. One of the key reasons was BAE Systems’ global footprint in regions such as South America and the Gulf. I was also keen to use a UK design because I felt this was particularly important for sovereign capability and UK prosperity.

“Furthermore, we needed a design which was flexible, could enter production quickly and had manageable through-life costs. The three main through-life costs are manning, fuel and the combat system. Leander has huge flexibility in its manning profile. It was by far most fuel-efficient design we encountered, and the BAE Systems combat system fitted naturally with all existing infrastructure in the UK. Fundamentally, we recognized that this ship has to work straight ‘out of the box’. It requires a straight forward engineering design that avoids any teething issues. Leander is a very practical warship with credibility, a degree of ruggedness and robustness, and delivering low risk lifecycle costs.

“We have a global campaign plan for the Type 31e program. We are actively engaged with more than 20 countries and our intent is to build a global warship export business based on Leander. The MoD has indicated it is willing to sign a business agreement alongside the contract to help industry export the Type 31e. That is very important to us and our export ambitions. This joint approach between the Government and the Royal Navy producing a proper business plan for exports has never been seen before.”

BAE Systems Type 31e Project Director Angus Holt said the UK MoD has adopted an entirely new approach with its latest new build program.

“The MoD is looking to procure something which is innovative both in the sense of the design, how its contracted and how its built, but also how we work together across the whole spectrum.” he said. “Handing the ship over in 2023 when the contract is not going to be placed until the first quarter of 2019 is a huge challenge to anyone in the defense sector. This has not been done in a long time on a complex warship. Another challenge the MOD has set is a fixed price, of nominally £250million per ship. When you take into account inflation aspects this actually reduces available spend considerably.

“There is a real challenge for us to look at how we design a ship with the best capability for the MOD. That is our key focus at the moment. We are looking to the supply chain for different ways of working and new ideas which allow us to satisfy this goal. We must produce a first-class warship, meeting key cost parameters, which the Navy can place in service around the globe in extreme conditions by 2023. Another aspect which is absolutely vital is the exportability of the ship. We need to develop a ship which other nations are looking for. There are opportunities developing around the world which we can now capitalize on with a flexible design like the Type 31e.”

BAE Systems Type 31e Chief Engineer Gavin Rudgley said the design draws from experience of several of our successful designs, the Khareef corvettes built for Oman, T45, T26 and the RCB2 OPV built for the Royal Navy.

“The MoD has commissioned the Type 31e as a replacement for the Type 23 in respect of its general purpose capability, global operations, effective warfare and combat suite, reasonable crew capacity, aviation and mission boat capabilities,” he said. “Maturity, adaptability, affordability and capability are seen as the key ‘win’ themes for the Type 31e program. It is expected to be around 4000 tonnes and 120 meters in length, accommodating 120 crew. The Navy want to see the vessels operating in Gulf conditions, there’s not a strong emphasis on ice capability or cold conditions, which also fits in well with exports.

“The Leander design incorporates much mature engineering and equipment from other programs such as Type 45, Type 26 and the River Class Batch 2 offshore patrol vessels. The boat bay and mission space is scaled from what has already been developed for the Type 26. And the HVAC [heating, ventilation and air conditioning] is based on practical experience, with both Khareef and Type 45. Leander uses the same combat management system being rolled out to Type 23, and also planned for Type 45, Type 26 and the Queen Elizabeth class carriers. It will further feature the 997 radar and Sea Ceptor anti-air missile system now entering service on Type 23 and ordered for Type 26. That drives commonality across the fleet, and provides the MoD with a solution that is already certified in-service, through its safety case, and cyber-assured.”

BACKGROUND

On 6 September 2017 the Government unveiled an ambitious new National Shipbuilding Strategy which meets the challenge set by Sir John Parker last November in his review of the sector. Sir John Parker’s independent report into British naval shipbuilding proposed far-reaching recommendations to transform the UK maritime industry and boost the prosperity of regions, shipyards and maritime supply chains across the country. The National Shipbuilding Strategy sees the Government accept Sir John’s recommendations and step up to what he called a prospective ‘renaissance’ in British shipbuilding. Building on the Government’s industrial strategy, it outlines an ambition to transform the procurement of naval ships, make the UK’s maritime industry more competitive, grow the Royal Navy fleet by the 2030s, export British ships overseas, and boost innovation, skills, jobs, and productivity across the UK. The strategy announced the Government’s plan to procure new Type 31e General Purpose Frigates. A price cap has been set of no more than £250million each for the first batch of five frigates. In line with standing UK policy on warships they will be built in the UK. The first ships are set to be in-service by 2023. Shipyards will be encouraged to work with global partners to ensure the vessel is competitive on the export market.

Cammell Laird background

Cammell Laird is one of the most famous names in British industry with roots tracing back to the early 19th Century. The business is located on the River Mersey, in the Liverpool City Region, on the West Coast of England. It is in the center of a marine cluster, with direct access to many support services. It has a 120-acre site with four dry docks, a non-tidal wet basin, large modular construction hall and extensive covered workshop. Cammell Laird specializes in shipbuilding, military ship refit, commercial ship repair, upgrade and conversion and heavy fabrication and engineering. It deals with a wide variety of projects ranging from specialist offshore conversions and fabrication, commercial ship-repair through to the refit and upgrade of highly complex naval auxiliaries. Cammell Laird is demonstrating its global competitiveness by securing a string of shipbuilding orders. The business is further active in the energy sector. It has become a hub of the offshore wind industry and it is offering its facilities and highly trained workforce of engineers for work in the civil nuclear sector and the offshore oil and gas sector.