Siemens Improves Subsea Ethernet Communication

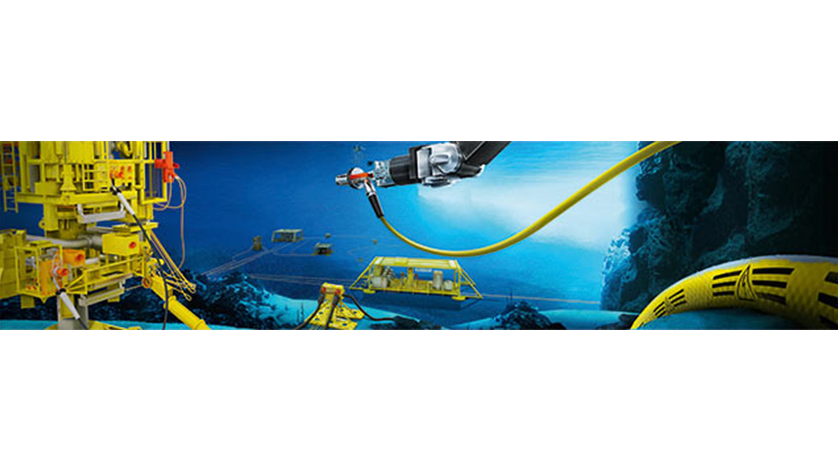

Siemens has successfully developed and tested a new cost efficient product for better subsea Ethernet communication. The Advanced Converter & Switch (ACS) is making it possible to communicate at higher data rates and over longer lengths, then with the current electrical distribution technology. The ACS increases precision and effectiveness of subsea communication. This transparent communication solution can be used for connecting to existing subsea fields, for field extensions or for new developments. Over all resulting in a simple and cost-effective solution for both brownfield and greenfield applications of subsea Ethernet. The ACS is qualified to industry standards and ready for the market May 2016.

The ACS is a reliable and cost-efficient alternative to conventional upgrades of existing subsea equipment from old communication standards to Ethernet and/or fiber. It does so by linking the existing, reliable and cost-efficient technology of copper cables with fiber technology for longer lengths which achieves high speed communication for longer distances in a subsea communication network. This includes communication between sensors and control systems subsea, as well as subsea to topside communication. The result is a product that can be installed to enhance communication and data transfer from brownfields and new developments on longer and more complex step outs.

Siemens has developed a fully-qualified product that can combine and convert various types of communication up to 84 km at 3000MBSL. Today, costly umbilicals, canisters and control modules are used to distribute and convert different types of signals over longer distances subsea.

Ethernet is commonly used technology for communication from platform or land to the sea floor, and for communication on subsea applications such as interfacing sensors and as the main communication tool between electronic control modules. Its capability to provide an extended capacity is due to the relatively high bandwidth. In line with conventional standards, Ethernet-based communication on twisted copper pairs is today limited to 100 meters, thus making communication limited within the confines of the same Christmas tree. Conversely, optical fiber is capable of longer distances and, if used instead of electrical lines, the maximum distance for distributing Ethernet is increased dramatically, making communication between different Christmas trees feasible.

The basic design of the ACS comprises one-atmospheric chamber housing, a PCB card (Printed Circuit Board) and a glass-to-metal penetrator on the copper side and glass-to-glass on the fiber side. This gives a field proven sealing for the one atmospheric chamber. Its modular design may be configured in various ways, providing the possibility to combine several fiber optic and/or electrical Ethernet interfaces integrated to a flying lead, sensor harness, umbilical termination, or even a subsea Ethernet switch. The solution is based on the well field-proven Siemens Subsea products, as it is based on proven distribution technology for fiber and electrical signals and umbilical terminations. Same sealing technology as used on the Siemens Advanced Fiber Terminations (AFT) and Advanced Cable Terminations (ACT).

Performance can be monitored continuously or when necessary and does not require reconfiguration if units connected to the electrical subsea interfaces are replaced or upgraded. Challenges in power consumption, EMC, signal monitoring and conversions have been solved with the development of the modular PCB card, specially designed for installation in existing and field proven subsea technology.