Video Plays Increasingly Important Role In Offshore Oilfield Operations

By: Timothy Gallagher

The ability to stream video in real time to, from, and within remote oilfields has grown in importance for energy companies, government agencies, and many other organizations. The more they rely on these data, the more these organizations struggle with determining solutions for backhauling and archiving rapidly growing data volumes and also finding the right video segments or images from among hours of files. The latest solutions solve these challenges and enable geographically dispersed stakeholders to more effectively observe and collaborate on a combination of subsea and topside operations.

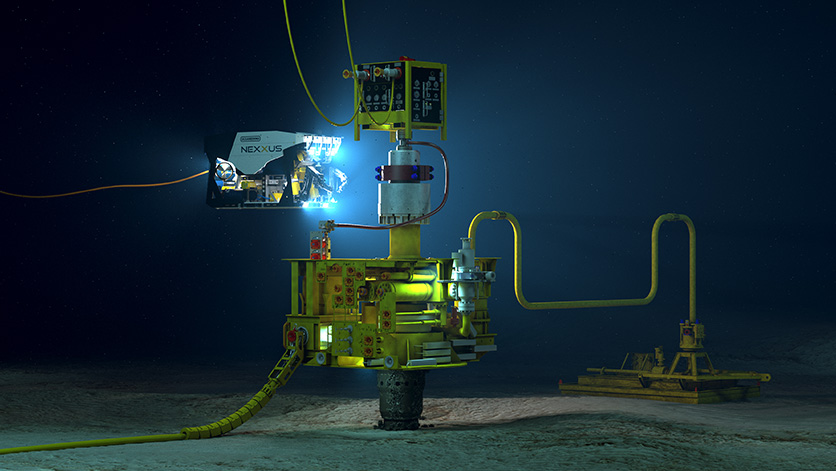

Subsea Hydraulic Well Intervention Oceaneering

Among the most powerful early examples of the considerable value of subsea video were the live images delivered in 2010 from the Deepwater Horizon oil rig atop the Gulf of Mexico’s Macondo exploration well. This live stream was transmitted continuously for more than three months from approximately 5,000 ft (1,524 m) below sea level and viewed by 20 million people each day. It influenced everything from crisis response and management to how policy and public opinion were formed during and following the incident.

Oceaneering delivered that live feed from a land-based location, demonstrating the cost and efficiency benefits of remote video monitoring for around-the-clock incident response management. Since then, video technology has continued to improve, and video data are being used for an expanding range of applications. Offshore video communication is now commonly used to optimize drilling operations and can also be used to extend exploration to deeper waters and more remote regions. It also enables collaboration between onshore and offshore personnel so they can improve decision making, preempt problems, or troubleshoot crises. Video can also provide a critical real-time look at all vessel, dockside, and remotely operated vehicle (ROV) operations in addition to drills and incident response activities.

Today, cameras are used throughout the oilfield for applications ranging from general closed-circuit television (CCTV) surveillance to process monitoring. They can be installed on multiple “observation” ROVs that surround larger ROVs and provide an enhanced operational perspective. Live video is also used topside to monitor equipment on rigs and support vessels. Video is also frequently streamed from refineries or from load operations at docks and ports. Providing access to these live video feeds reduces the number of phone calls that must be made in order to confirm, for instance, that a crane is working, that necessary material is on the deck, or that operations are proceeding as intended.

Video is also used to monitor pressure gauges and other instruments, as organizations augment raw instrumentation data with the output of both fixed and moveable cameras. Fixed cameras can remain focused on a single gauge, while moveable cameras can pan in and out to provide views of different gauges in a given area on the drill deck.

Additionally, video can be used to support photogrammetry services in which images are used to create maps, drawings, measurements, or 3D models of what is being observed. There are other emerging purposes for video, including converting the video delivered by ROVs to digital point-cloud data that can be used to facilitate remote piloting.

Video also can be extremely useful in the aftermath of severe offshore weather events. The ability to remotely assess storm damage reduces the expense and risk of using flyovers to ensure, for instance, that a helipad is intact, clear of debris, and accessible. If damage is seen, the organization can make all necessary repair plans and bring the correct replacement parts and equipment on the next flight.

Today’s solutions encompass a variety of specialized video capture, storage, and integration tools. They also require enterprise-class networking, archival storage technology, and service-provisioning capabilities tailored to the unique needs of remote deployments in extremely harsh and variable conditions. Video archiving is a particularly important piece and must include encoding and video media management, with support for tagging, indexing, and geospatial integration to simplify video retrieval and analysis. Each of these solution elements must be optimized for operation in extremely harsh and variable conditions.

Deploying a Solution

The solution starts with explosion-proof deck video cameras that should be hardened for the most rugged environments and include full pan-tilt-zoom (PTZ) capabilities, low-light technology, Internet protocol (IP) networking, and support for multiple compression formats. Solutions for subsea lighting are particularly important in order to optimize video image quality. The latest solutions take advantage of advances in LED lighting that significantly improve image resolution and reliability.

As stated earlier, live video streaming is becoming more and more commonplace. Once the video is acquired, technology is needed for streaming and transport. Solutions must be capable of supporting high volumes of feeds—as an example, Oceaneering typically carries between 200 and 250 live subsea video feeds simultaneously from its ROVs. In one project, there were 29 ROVs in the water at any given time, each with up to six cameras that were collectively delivering more than 100 live video feeds to the customer. There are already bandwidth challenges at these feed volumes, and these challenges will only intensify as video files move beyond standard-definition (SD) to high-definition (HD) and even 3D formats.

Standardized view of video search results.

Roughly 30% of this video is viewed on mobile devices, and getting it to users on the platform of their choice requires the use of high-performance H265 video compression technology. This doubles image resolution as compared to earlier formats at the same 50 kilobit- per-second (Kbps) stream speed that is typical of the offshore environment.

Video transport requires a robust enterprise-class network. Whereas consumer video service providers enable millions of viewers to watch thousands of videos, an offshore video communications infrastructure is designed to enable, say, 100 users to access upward of one million videos. The wireless networking infrastructure is virtually the same for both systems, however, and the offshore version must operate in one of the world’s most unforgiving environments, enabling video distribution from ship to ship, from rigs and ships to shore, and from rig to rig, while also supporting other demanding voice and data communications requirements.

For instance, subsea tools, such as rotary brushes used for equipment cleaning, are continuously monitored via a combination of video and other data sources. Video is used to observe effectiveness, while the other data facilitate ongoing analysis. Ultrasonic testing (UT) tools also continuously transmit data, and digital radiography tools can generate as much as 50 megabytes of data per hour. Meanwhile, other tools are used around the clock for real-time monitoring of critical assets, such as blowout preventers, that must be observed continuously and repositioned as necessary.

The bandwidth budget must also include videoconferencing, which is increasingly used between rigs, platforms, vessels, and onshore headquarters. The average bandwidth usage for an oil rig is approximately 2 megabytes per second (Mbps).

All infrastructure elements that are required to support video, data, and telemetry transmission must be transported long distances to remote offshore locations. The most effective approach is to configure this infrastructure onto a portable skid that can be dropped onto the back deck of a rig or vessel. Today’s skids can be configured to include all necessary voice, video, and data communications capabilities. Several networking implementation options are available, including point-to-point, vessel-to-vessel, multi-point field, and vessel Wi-Fi. Vessel-to-vessel mesh networking capabilities are also available, enabling a rig and multiple vessels to transmit video, data, and telemetry and to share bandwidth.

Once the video capture, streaming, and transport elements are in place, the next step is to develop a solution for archiving, retrieving, and analyzing. Organizations must be able to access drilling footage from any location at any time, so they can decide on the best solutions to day-to-day problems or questions. Today’s video management solutions are integrated with inspection overlay and video tagging systems; these systems provide support for video analytics and automatic anomaly tagging and feature standard or customized viewing capabilities.

A typical project might generate 1 to 2 terabytes of data each day, making storage a challenge. As file sizes grow with the move to HD, 3D, and high-resolution video compression formats, archival data volumes can overwhelm enterprise storage resources. Complicating the picture, storage on physical media can make sharing, retrieval, and analysis extremely challenging. For these reasons, the industry is moving to more convenient and secure cloud-based storage models.

Video tagging and indexing are also important for simplifying retrieval. Today’s solutions deliver full digital video recorder (DVR) functionality and take advantage of geospatial integration to improve convenience. Users can tag interest areas to analyze later and search by comments, tags, or timestamps. They can also attach documents or pictures via metadata content management and use thumbnails to browse and index the entire video timeline, thus cutting the time needed to identify areas of interest. Playback modes, including fast and slow forwarding and rewinding, enable users to quickly get to a section, pause and review it, and then return to the live feed. It is also possible to extract and deliver a short section to someone’s desktop without having to download the entire file.

Video retrieval convenience is further improved through geospatial integration. The coordinates for video source locations are automatically inserted into the stream via key length value (KLV), enabling users to request, for instance, that the system show them all of the video in the Gulf of Mexico. Users can then click on an individual ROV in that area and issue a “follow” instruction. Another application for geographic video tagging is to automatically bring up inspection images from a specific pipeline segment as part of an asset integrity program.

Some operators have laid transponders on the vessel floor so that information about their subsea projects can be gathered from the seabed. Larger ROVs have an internal inertial map system that is used to calculate the ROV’s location.

The final step in deploying an offshore video solution is to set up the necessary voice and data communications services, including a very small aperture terminal (VSAT), along with radio, cellular voice and data communications, CCTV, ROV-to-CCTV broadcasting, and Wi-Fi. Capacity can be increased for operations needing additional bandwidth by adding services, including longterm evolution (LTE) communications and subsea fiber integration to connect subsea equipment together and back to shore. For vessel-to-shore communications, standard maritime satellite communications services now support data rates of 512 Kbps, and the industry is moving to a 1-Mbps bandwidth standard.

In order for the entire oilfield to communicate in real time, it is necessary to move to optical subsea communications. Previously, ROVs could only gather data from subsea equipment by moving to locations in the field where they could download via acoustic or optical communications. Likewise, they could only send data to the surface in batches via the fiber embedded in their umbilical cables. As the industry solidifies interoperability standards for optical communication modems that can work over distances of 492 ft (150 m) or more, there will be the opportunity for the entire field to communicate in real time.

Other Support

Offshore operators should also consider the benefits of outsourcing any or all of their video requirements to information technology (IT) and communications systems support teams. Highly skilled personnel can operate wherever they are needed, whether on the rig or aboard supporting inspection, maintenance, and repair (IMR) vessels. These teams can be dispatched to install and maintain all communications and data infrastructure throughout the oilfield, and they include senior-level network engineers who can handle physical installation and also travel with the operation as required.

Video has become a standard tool for optimizing offshore operations. While it can be difficult to implement all necessary capture, streaming, transport, storage, and communications elements in the harsh and variable offshore oilfield environment, today’s solutions overcome these hurdles and can be supported by skilled technicians who know how to install, operate, and maintain the industry’s increasingly sophisticated offshore video communications infrastructure.