Industrial Li-Ion Batteries for the Sustainable and Safe Use of the Oceans

Lithium-ion batteries are used for a wide range of activities and applications in the oceans such as to power vehicles, sensors, and energy storage systems, as well as to electrify oil and gas production. Kiel-based SubCtech has solutions for a sustainable, reliable, and safe energy supply with Li-Ion batteries.

In the spirit of UN’s Decade of Ocean Science for Sustainable Development, and the advance of the Blue Economy, SubCtech is on a mission to revolutionize underwater technology.

Over the years, SubCtech has tracked the ever-increasing demands for subsea power capacity from the offshore industries. The company recently responded by introducing a new Li-Ion battery series engineered specifically for large subsea storage, vehicle propulsion, and the electrification of oil and gas production facilities.

Offshore developers acknowledge that as exploration of oceans advances, so must the need for a more sustainable and safer approach. With the aim of making technologies more efficient and using ocean resources cost-effectively, future solutions must prioritize protection and sustainability.

RELIABLE, ROBUST & SAFE

SubCtech supplies batteries that not only make one-way batteries superfluous, but also make applications safe, reliable, and efficient, and therefore sustainable. Over the past 15 years of battery technology development, SubCtech has supplied batteries to underwater markets around the world. In addition to the standard batteries (COTS), which replace disposable batteries or older technologies such as NiMH or lead-gel, underwater vehicles or production facilities are equipped. Voltage, capacity, power and therefore size and weight can be scaled to fit different user solutions with a set of standard components, with a very long service life of 15 to 25 years. The consequent use of standards, from the supply chain through to production, reduces users’ costs and overall CO2 footprint.

Developed to be used in manned vehicles and subsea production facilities, the Li-Ion batteries have been developed with maximum safety in mind, following the principles of IEC61508. The batteries are also subjected to extensive shock & vibration, rapid temperature cycling and EMV tests. Such qualifications are compulsory for vehicles and subsea operations in the oil and gas market, as service or even failure would cost millions of dollars and even cause massive damage to the oceans and, therefore, human life.

At present, SubCtech is working on the future revision 5 of the API17F to support the concept of fully electric production systems. With this standardization and focus on functional safety, the safety of future electrical underwater systems is significantly increased.

With major companies, standards for safe operation, maintenance and obsolescence, commissioning and removal, and also data communication, are an ongoing concern for product development. SubCtech therefore also supports the further development, standardization, and implementation of the framework of SIIS (Subsea Instrumentation Interface Standardization). With its long-term focus on safety-critical applications, SubCtech is ideally positioned to meet the current and future requirements.

SCALABLE ENERGY SOLUTIONS

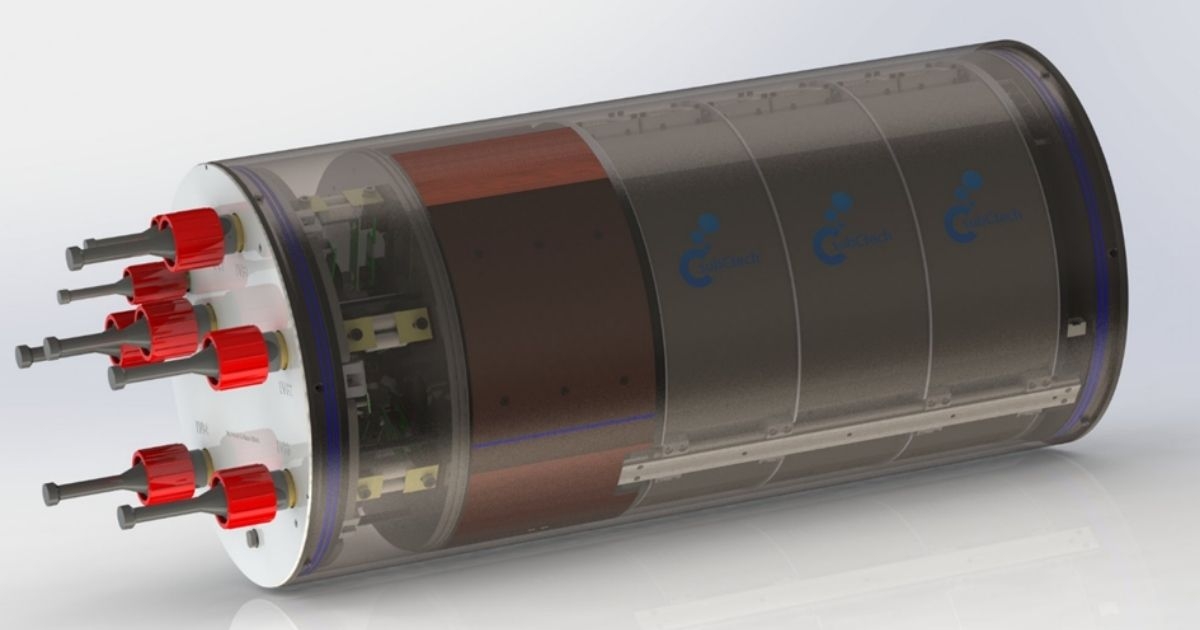

The energy of the batteries is easily scalable by stacking different numbers of SmartPowerBlock™ (SPB) submodules. Power distribution (PDU), voltage conversion, and data interface can be added to the single titanium or duplex steel housing completing a battery system. Combining these functions in a single pressure housing reduces the number of subsea connectors and simplifies system integration.

Battery cells with Li-Ion technology offer enormous advantages in terms of energy and power density at moderate costs. Due to the flexible design, the charger can be external or can be integrated into the pressure housing, e.g., for AUV/ROV docking stations or subsea storage solutions. SubCtech has developed DC and AC converter technology that allows high charge power and therefore short charging times without complex cooling.

With our own laboratory for examining Li-Ion cells, optimal operating parameters are configured for robust, reliable, and scalable battery systems. For optimal operation, important characteristics of the battery are the state of charge (SOC) and the state of health (SOH). Aging of the cells is largely determined by the operating conditions e.g., the temperature. SubCtech calculates the battery systems with an available energy EOL under subsea conditions. The nominal energy of the battery is thus higher than the required one, but the battery will reliably and precisely deliver the energy and power that is necessary over its entire service life.

The ability to adjust operating parameters during operation without retrieving and service on board enables simple testing at significantly reduced costs. We prevent surprises through supposedly cheap solutions with a higher risk of failure.

Areas of application for our Li-Ion Batteries are ROV, AUV, offshore oil and gas and Energy Storage Systems (ESS) with a design life of 25 years and UN T38.3, MIL-STD, DNV-GL or API17F qualifications.

BUILT TO LAST

Another product feature that optimizes OPEX and real-world sustainability is the pressure housing. Unlike traditional duplex and 316L steel canisters, SubCtech specializes in the use of titanium. For operation, it is important that damage such as scratches on deck or underwater does not affect the function of our titanium housings. A coating and corrosion protection (CP) is not required and so reduces the possible entry of pollutants into the water. In contrast to regular expensive maintenance of subsea structures with ROV support, titanium housings are 100% maintenance-free over their design life. Our connectors are also made of titanium. Galvanic isolation is only needed for other non-titanium materials such as frames. An important advantage is that there can be no crevice corrosion under the seals—the probability of failure is zero. Since SubCtech also produces large titanium housings, battery systems can also be easily scaled to different water depths and form-factors.

Permits for air freight, export and import, as well as special permits, have been obtained from the German LBA, US DOT, IATA, and other authorities.

With our standardized, long-life Li-Ion batteries, we make durable underwater technology reliable and cost-effective. Our products ensure the highest levels of safety and minimalize OPEX. The transition to "all-electric" subsea technology not only helps us protect the oceans but enables a sustainable use of natural resources.

For more information, please visit: www.subctech.com

This story was originally featured in ON&T Magazine's October 2021 issue. Click here to read more.