March Feature Story - Teledyne Marine Interconnect

Innovative Fiber Optic Networking Solutions

By: Teledyne Marine Interconnect

Subsea fiber optic networks are an integral part of our modern ocean systems, designed for transmitting and receiving reliable, accurate data among and between the different sources and users of data. These can include downhole sensors, wellhead equipment, subsea infrastructure, subsea pipelines and ship- and shore-based control facilities. The data are used for a myriad of applications, from monitoring the health of a pipeline in an oil and gas field to detecting seismic activity on the seabed to research climate change, among many others. As sensors have become more sensitive and reliable, interconnect systems have also evolved. The need for enhanced reliability and the ability to collect complete data is ever increasing. Data provide a window into a world we can’t visually see, and the trend continues to point to gathering more and more data as sensors and systems develop further into longer step-outs and higher bandwidth. Subsea networks will, in turn, require modular connectivity using interconnect systems capable of supporting this high bandwidth.

Subsea fiber optic networks utilize wet mateable connectors.

Fiber optic interconnect systems are often found in subsea vehicles that perform a wide range of tasks from surveillance to monitoring and pipe tracking to actuating subsea valves and hydraulic, electrical, and fiber optic connectors. Submersible gliders, autonomous unmanned vessels, and remotely operated vehicles (ROVs) all are important elements in both the oceanographic and energy industries to perform functions in locations that divers or boats cannot access safely or economically. In these cases, it is imperative that the interconnect systems function reliably to justify the economics of these complex instruments.

Interconnect technologies currently available on the market range from small-form-factor, single-channel submersible fiber optic connector sets to multi-channel wet-mateable connectors designed to be mated underwater at full ocean pressure via ROVs or divers. A complete assembly, often referred to as a jumper or flying lead, is designed to connect subsea nodes, junction boxes, and instruments together to comprise a networked system.

Whether the application consists of a complex subsea oil production field or an ROV designed to inspect shipwrecks, the design of the interconnect system demands considerable and critical attention since failure to communicate data properly can result in a costly or even irreplaceable loss. It is, therefore, critical to properly match the connector configuration to the application to optimize the value for the cost while still guaranteeing reliable data relay for the expected life of the system, whether it’s 6 months or 30 years.

Fiber optic interconnect technologies currently available to the market are listed below:

• Optical dry-mate submersible connectors

–Typical applications include cameras, riser monitoring systems, submersible vehicles, and subsea sensors

• Optical wet-mate connectors and penetrators paired with optical cable terminations

–Typical applications include subsea control modules, data transmission systems, umbilical terminations, and junction boxes

• “Active” Flying Leads for electrical/optical conversion

–Typical applications include subsea observatories, seismic monitoring systems, subsea oil and gas pumping, processing and boosting, littoral and deep-sea persistent surveillance systems, and configurable port and harbor security system networks

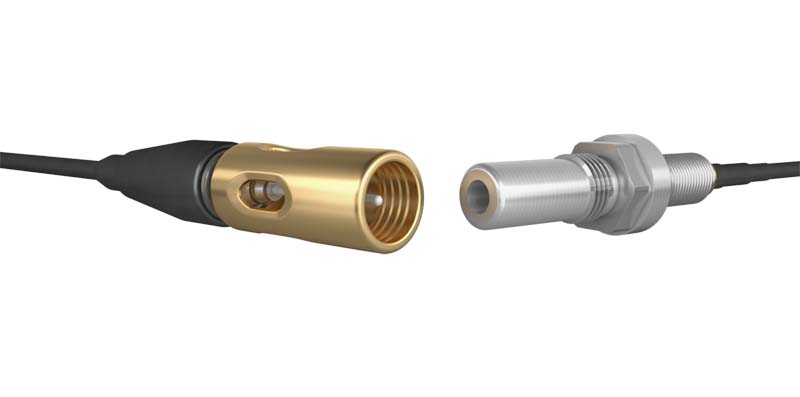

Optical dry mate submersible connectors

Even as subsea instruments are getting increasingly more sophisticated, the demand for small-form-factor optical connectors has increased. With the linking of multiple optical sensors comes the need to reduce weight and size. Smaller connectors are a solution as long as the optical specification requirements are met. In response to this trend, Teledyne Impulse-PDM developed the Omicron, the smallest single-way underwater-capable fiber optic connector in the industry today, rated for an operational depth of 5,000 m and an insertion loss of less than 0.5 dB. The Omicron series is engineered for use on submersible cameras, riser monitoring systems, sensor systems, and other applications that involve data and signal communication in harsh or challenging environments.

Teledyne DGO's 153 Fiber Optic Connectors.

Teledyne DGO also offers a 153 series, a fiber optic assembly that accommodates up to 15 channels. The 153 series is rated up to 10,000 psi, with operational temperatures from -50°F to +160°F, allowing reliable operation in challenging conditions where failure is not an option.

Optical wet mate connectors and cable terminations

For fiber optic networks found in both subsea oilfields as well as scientific observatories, reliability and the ability to handle high bandwidth are both crucial elements to a functioning network. Teledyne ODI designs complex engineered solutions for subsea interconnect applications, meeting challenges brought on by high pressures and temperature extremes in turbid and saltwater environments. The Rolling Seal Hybrid (RSH) is the industry-standard, multi-channel, underwater optical connector for subsea field operations requiring high-speed data transmission via optical fiber. The patented Rolling Seal design functions by excluding water and shuttling silt away from the region where the optical ferrules are brought into contact, creating a clean, oil-filled conduit for the optical ferrules to connect. The result is a reliable low-loss optical throughput. Coupled with field-proven optical cable terminations, fiber optic networks that operate continuously for over 25 years can be developed for multiple applications.

Teledyne PDM’s Omicron Fiber Optic Connector.

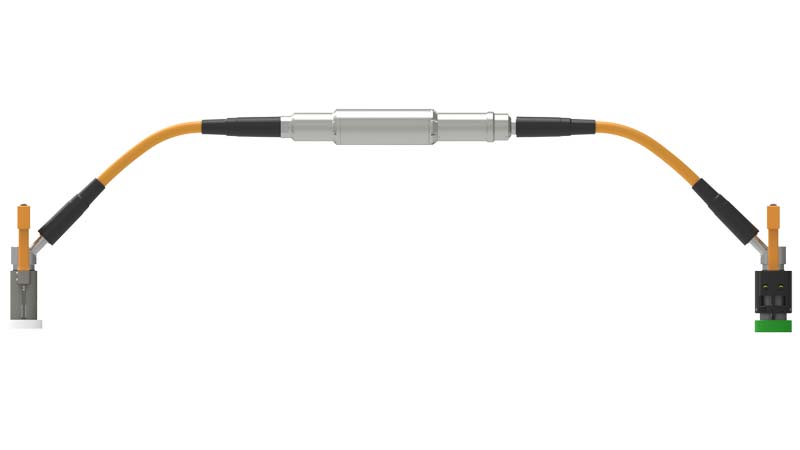

Active Flying Leads and E/O conversion

Traditionally, Flying Leads (or jumpers) have been considered a passive element in subsea infrastructure, meaning that power and data move through the system without interference or modification. The introduction of Active Flying Leads and the evolution of subsea fiber optic connectors provide a platform to solve future challenges in subsea data communication.

Identified as Active Flying Leads (AFL), this technology allows for the use of electronics integrated into a connector or in-line with the jumper and, in some cases, converting from different methods of communication that the equipment utilizes, transforming the Flying Lead into an active component in a subsea data transmission system. The AFL platform consists of functional electronics housed within a qualified atmospheric chamber that can be placed within a pressure-balanced, oil-filled (PBOF) hose. Teledyne DGO’s glass-to-metal sealed penetrators provide fail-safe pressure barriers within the chamber for reliable performance under the extreme pressures found in deepwater subsea fields.

Teledyne ODI’s Electrical Optical Flying Lead.

The AFLs can also be used to extend communication to lengths that were previously not possible. The flagship product within the AFL family is the Electrical to Optical Flying Lead (EOFL). The EOFL converts a fiber optic signal through a hybrid fiber optic wet-mate connector and produces an electrical Ethernet signal through a 12-way electrical connector on the other end. The conversion from optical to electrical is accomplished in a compact one-atmosphere internal chamber. This new product may be used in place of more complex equipment such as secondary nodes and junction boxes or distribution manifolds, allowing a simplified infrastructure with reduced cost and risk.

The AFLs are retrievable with an ROV for maintenance and upgrades, if necessary, allowing for further operational cost savings. They can also be used to locate sensitive equipment or experiments further from the shore or in more remote areas than previous technology allowed. The EOFL can be used up to depth of 4,000 m (6,000 psi) and at temperatures between -5°C and 40°C. Accelerated Life Testing has determined that the system will operate reliably for 30 years.

Modern and emerging sensors and systems now demand more options for data transmission networks. This trend will drive increasingly complex sensors and systems. Subsea networks will, in turn, require modular connectivity using interconnect systems capable of supporting higher bandwidth requirements. It is critical to understand all the underwater-capable fiber optic technologies available to design a network that is engineered for the application, both in specification and product life expectation, to ensure a cost-effective and reliable data transmission system.

About Teledyne Marine Interconnect

Teledyne Marine Interconnect provides mission-critical systems to the oil & gas and oceanographic industries. The company’s technology and products provide power and broadband data transmission interface assemblies as well as instrumentation for corrosion and erosion monitoring of pipelines. Equipment is designed to operate at high pressure in the harsh subsea environment.